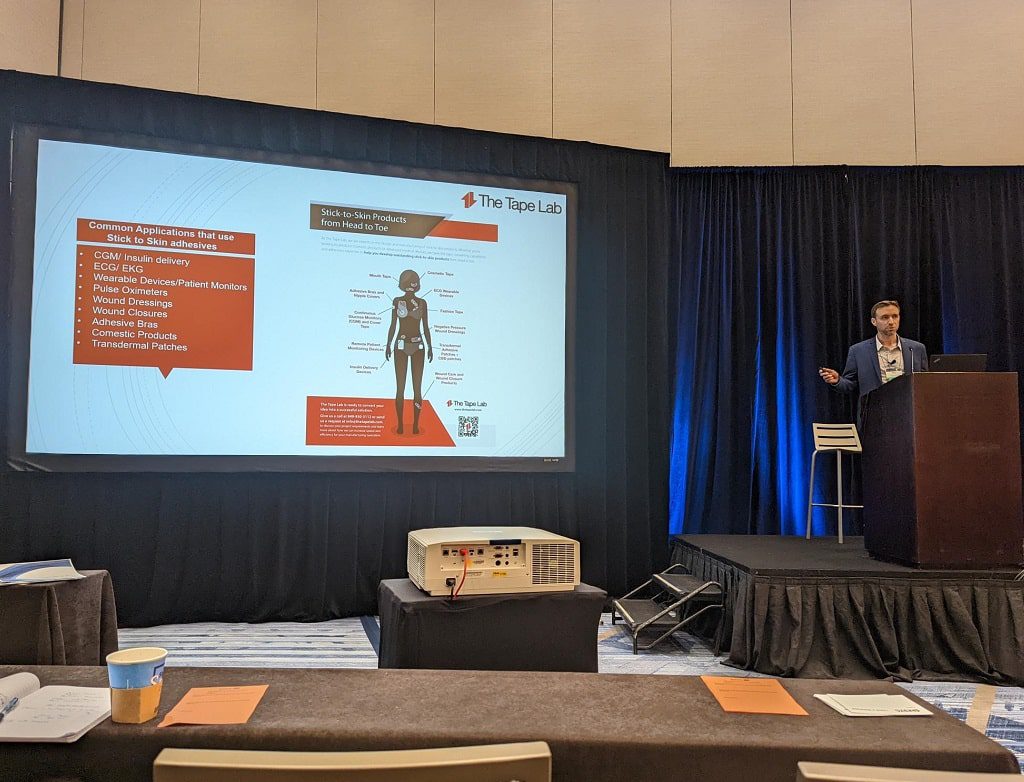

Introduction: Welcome to The Tape Lab’s official blog, where we share valuable insights and expertise to empower biotech companies in navigating the intricate world of medical device regulations as it pertains to medical adhesives and converting. Today, we delve into the critical topic of 510K medical adhesive consulting and how our team can guide you through the FDA clearance process with confidence and ease.

Unlocking the Potential of Your Innovation: As a biotech company, your primary focus is on creating revolutionary technologies that can transform healthcare. However, understanding the complex landscape of FDA regulations and compliance requirements can be overwhelming, especially when you are primarily driven by data scientists and electrical engineers. This is where The Tape Lab steps in as your trusted partner, offering unrivaled expertise in adhesive solutions and regulatory compliance.

Collaborative Consulting for Seamless Compliance: At The Tape Lab, we firmly believe in bridging the gap between innovation and compliance. Our team of experts collaborates closely with your company to gain a deep understanding of your unique medical device and its intended application. By asking the right questions and conducting meticulous analyses, we help you develop a robust plan that ensures your device meets the rigorous standards set by the FDA.

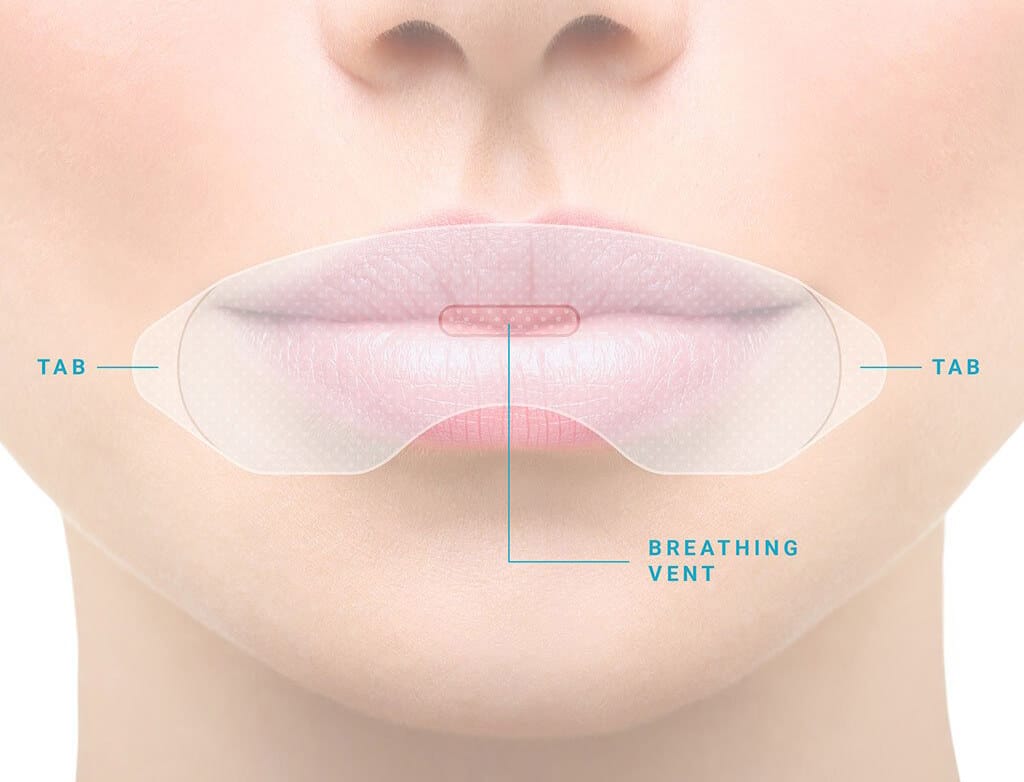

Refining Design, Materials, and Manufacturing: Our consulting journey begins by evaluating and refining your device’s design, materials, and manufacturing processes. We consider both short-term and long-term factors, ensuring scalability, prototyping, and the selection of biocompatible materials. Our goal is to optimize your device for success, addressing crucial aspects such as functionality, performance, and adherence to regulatory standards.

Prototyping for Precision and Performance: Prototyping plays a pivotal role in our consulting process. Leveraging our state-of-the-art facilities and expertise, we create accurate prototypes that bring your vision to life. These prototypes serve as tangible representations of your device, enabling us to assess functionality, performance, and compliance with regulatory standards. Through iterative rounds of prototyping, we refine and enhance your device, moving it closer to regulatory clearance.

Strategic Collaborations for Manufacturing Excellence: To ensure a seamless transition from prototype to production, we facilitate strategic collaborations with trusted medical converters. These partnerships connect you with qualified manufacturers who possess the capabilities to produce your device’s components. By involving converters early in the process, we ensure seamless integration between design and manufacturing, optimizing layout and addressing any complexities that may arise.

Comprehensive Testing and Documentation: At The Tape Lab, we leave no stone unturned when it comes to testing and documentation. We develop rigorous testing protocols to evaluate your device’s adhesive performance and compliance requirements. Through our extensive network of accredited testing laboratories, we identify the most suitable sources for comprehensive testing. We meticulously analyze the results, making necessary design, adhesive, and liner adjustments to meet the highest safety and performance standards.

Navigating the FDA Approval Process: Once your device and its adhesive components are ready, we assist in compiling the proper documentation, ensuring that all materials touching the skin meet FDA standards. We work diligently to identify predicate devices using similar materials, leveraging prior use cases to strengthen your 510K application. Throughout the FDA clearance process, we stand by your side, representing your interests in meetings with the FDA. Our expertise in adhesive solutions and biocompatibility testing protocols ensures that your device receives the attention it deserves.

A Partner in Your Success: At The Tape Lab, we understand that the FDA approval process is both intricate and dynamic. While the exact timeline for approval may vary, our commitment to your success remains unwavering. We keep you informed throughout the process, providing updates on progress, results, and any necessary adjustments required to achieve compliance.

Conclusion: Simplifying the 510K process is our mission at The Tape Lab. We offer unrivaled expertise, collaborative consulting, and a customer-centric approach to ensure your journey to FDA clearance is smooth and successful. Choose us as your trusted partner, and together, we can revolutionize the healthcare industry with confidence. Contact us today to embark on your path to FDA clearance and bring your transformative medical device to the world.