+1 949-930-3112

Call to request a quote

A lot of people ask: What is Pressure Sensitive Tape? The key differentiator of a pressure sensitive tape from other types of adhesives is that no activation by water, solvent, or heat is necessary to exert a strong adhesive force towards diverse materials such as paper, glass, wood, plastic, or metal. The Pressure Sensitive Tape Council (PSTC) defines Pressure Sensitive Tape as a continuous flexible strip of cloth, paper, metal or plastic coated on one or both sides with a permanently tacky adhesive at room temperature which will adhere to a variety of surfaces with light pressure (finger pressure) with no phase change (liquid to solid) and usually on a roll. The Tape Lab also offers many varieties of flexible materials without PSA applied to them like Films (PE, PET, PP, PC, TPE), foams (PE, PVC, Silicone, PU), Woven and non-woven fabrics and vinyl.

Pressure sensitive adhesives work as a result of three unique properties: Adhesion, Cohesion, and Tack. These three properties balance each other out and can’t work without one another, meaning that it is impossible to have a tape with 100% of each. Adhesion is the bonding strength of adhesive to substrate. Cohesion is the inner strength of the adhesive. Tack is the immediate grip of the tape (adhesive) to substrate (object).

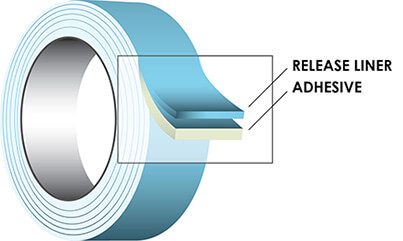

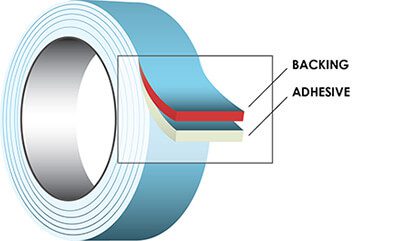

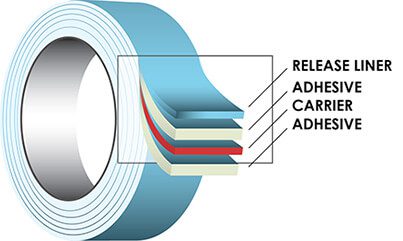

When defining a type of tape it comes down into its components. There are typically three components: the adhesive, the carrier, and the release liner (or backing). Not all tapes will feature all the components. There are also three standard compositions of tape: adhesive transfer, single coated tape, and double coated tape.

The release liner is commonly a paper or film that has been coated on both sides with a silicone release agent. Adhesive transfer tapes can come as a rubber, acrylic or silicone adhesive. Examples of adhesive transfer tapes include tapes for envelope & bag sealing, graphic attaching, laminating two indifferent substrates and splicing.

Some Single coated tapes come on a liner and some are self wound. The carrier can be any flexible material, including paper, polymeric film, foil, foam, nonwoven/woven cloth. If the single coated tape is self-wound it will have a release coating applied to the back side of the carrier. There are also single-coated tapes, such as filament tape & duct tape that feature reinforcements of woven cloth or glass strands to keep them stable during the process of making the tape. Examples of single coated tapes are boob tape, stick to skin tapes, electrical tape, masking tape, carton sealing/packaging tape.

The tape is then wound with a release liner, commonly paper or a film that has been coated on both sides with a silicone release agent. There are a variety of carriers used to make double coated tapes. Most flexible materials can be used as a carrier. Some examples of carriers are: a polymeric film (PET, PE, PP, TPE). The adhesive (acrylic, rubber, or silicone) may be the same or different on either side of the carrier, as well as offering different coating thicknesses (also called coat weights). Some examples of double coated tapes are bonding tapes, mounting tapes, VHB (acrylic foam tapes) tapes, carpet tapes and hair tapes.

When you think about tape, the entire purpose of it is to attach to something or to to bring two or more substrates together. Mounting Tape, Bonding Tape, and Attachment tape all convene the same use factor: holding things together or attaching to something. They are used for attaching, mounting, bonding or joining two or more materials together. Mounting, bonding, and attachment tapes come in thicknesses from .001" to 1" thick.

We offer 3M™ VHB™ Tapes, which offers outstanding durability for long-term performance. It resists cold, UV light, temperature cycling, moisture and solvents. It can seal against environmental conditions and offers design flexibility by expanding the range of material options for high impact visual combinations.

Our adhesive backed products are used by large and small design firms, retail merchandisers, and manufacturers of corrugated displays, fixtures, and signs to hold together their POP displays.

Packing tape is typically meant to describe the sealing of a box or package. Packaging and box sealing tapes are made of a backing material such as Polyester (PET) or Polypropylene (PE) with a rubber or acrylic adhesive. Typically stock in a box roll sizes are two to three inches wide.

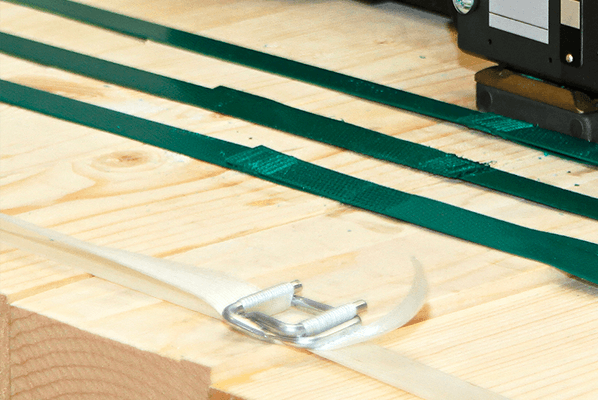

The Tape Lab strapping and filament tapes are used because of their robust characteristics in many different applications. Many of our high-performance strapping tape is also weatherproof, non-aging and resistant against most chemicals.

Safety Tapes, by nature, were designed and implemented to show caution or danger. They can prevent and warn people of hazards in any open space. Safety tape can help to prevent slipping and provide illumination or reflectivity under certain conditions.

The Tape Lab engineered solutions are tailored to meet the needs of our customers, whether to protect the surface, keep your edge, or protect those in between places. We help customers protect the surfaces of their parts and shield them from all types of manufacturing.

Ultra High Molecular Weight (UHMW) tape is a slippery film with a pressure sensitive acrylic adhesive on one side. It is the ideal material for applications requiring high slip and durability Our UHMW tapes protect surfaces from abrasion and induce a "slip plane" effect to allow contact without wear. UHMW tape reduces squeaks, rattles and other noises that can occur with movement of touching surfaces.

Fill out the form below with as much detail as possible, and we’ll get back to you right away.