The science of skin has come a long way in recent years, and transdermal patches are now a widely popular delivery method for a host of cosmetic, therapeutic and pharmaceutical treatments. Having gained widespread acceptance among consumers, the market for stick-to-skin patches can be very lucrative. To speed the development process and avoid costly issues, here are some things to consider when embarking on transdermal patch development.

The market for transdermal patches

Whether you’re talking about B12 patches, melatonin patches or even delivery systems for manuka honey, transdermal patches are in high demand. Overall, the market for transdermal patches was estimated at around $17.6 billion in 2020. Projections show that growing to around $30.5 billion by 2026.

Many companies are looking at manufacturing CBD patches in particular because the CBD market alone is estimated at nearly $3.5 billion, with projections showing significant future growth. CBD sales are expected to reach roughly $13.4 billion by 2028.

However, taking advantage of the transdermal patch market is no easy feat. In 2019, the CEO of one pharmaceutical company estimated that “the cost of developing a novel molecule-patch combination is nearly $2 billion.” But that same CEO estimated “the cost of developing a generic transdermal patch is less than 5% of the cost of a novel patch.”

This is where a tape converting partner can provide significant value. Instead of reinventing the wheel and incurring all the associated costs, a converter can provide tried-and-true methods that speed product development and eliminate headaches in the process.

For tips on how to take stick-to-skin products from concept to commercial production, download our ebook, Designing and Producing Wearable Stick-to-Skin Products.

Converting services for transdermal patches

Transdermal patch development is almost always easier, faster and cheaper when done in partnership with a tape converting services company. That’s because an experienced tape converter that can both formulate custom adhesives for transdermal patches and has the capabilities to die cut and package your patches can assist at nearly every stage of the product development process — from prototyping to packaging.

An experienced converting partner can help you:

Design your transdermal patch

- A knowledgeable converter can help you design a delivery system (i.e., matrix patch or pre-dosed patch) that can deliver the intended therapeutic through the adhesive layer.

- Sizing of the patch and location on the body for the patch are paramount in the success of the product. An experienced tape converter who knows the transdermal and stick-to-skin market is essential for the success of your overall design.

Select the right type of pressure sensitive adhesive

- Ensuring user comfort and avoiding skin damage is always paramount in any stick-to-skin application.

- Adhesives have to maintain their hold while managing moisture from sweat, water, oil and other bodily fluids.

- Users also need to able to remove products safely and comfortably.

Ensure consistency in the finished product

- Consumers expect (and regulators demand) a consistent payload or dosage from transdermal patch products.

- Reliable converting processes help ensure each patch delivers a consistent experience.

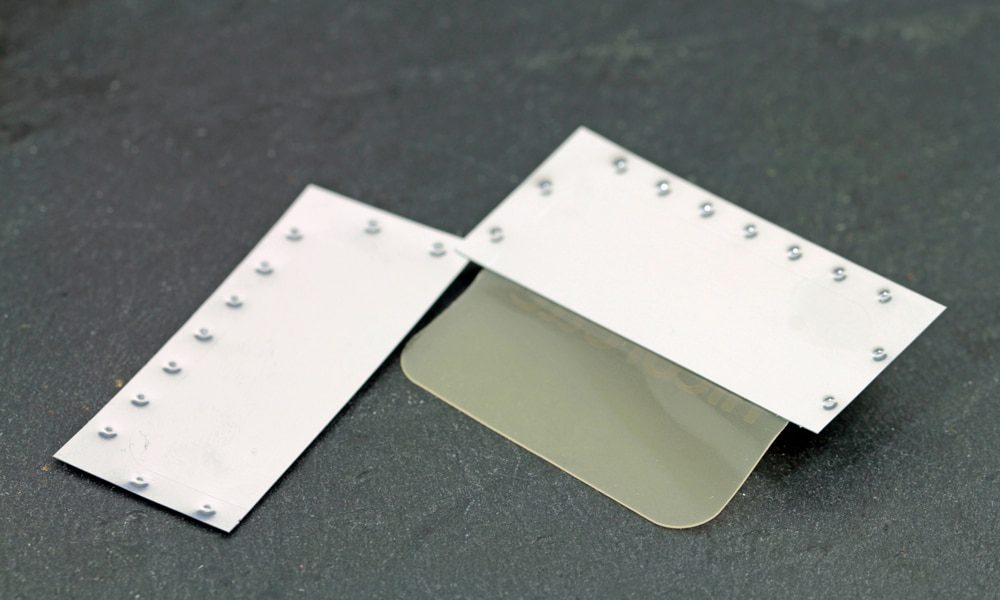

Choose materials for the carrier and liner layers

- A converter with ties to major suppliers can help you source the premium materials you need to make products that stand out in the marketplace.

- Extended tape liners make products easier to apply for consumers.

- A converter with full packaging resources can be your full turnkey solution to launching and maintaining a consistent supply chain.

Cut materials to the desired shape

- Whether you want squares, ovals or a butterfly shape, a converter with an array of die cutting, slitting and sheeting capabilities can create the ideal shape for your application.

- A trusted partner can also help organize production to cut down on wasted material.

Maintain regulatory compliance

- A converter that is ISO 13485 certified has proven they will adhere to strict guidelines to ensure quality control and help you avoid any regulatory issues.

Streamlining product development

Transdermal patch development is a complex process with a lot of hurdles to overcome before you can get products into the hands of your customers. That’s why the best go-to-market approach is often to seek out a converting partner that offers full service private labeling for every aspect of your patch. For example, The Tape Lab can formulate safe stick-to-skin adhesives, laminate materials to create the finished patch, die-cut patches to the appropriate size and even package products for patch manufacturers. This allows us to act as a one-stop shop for all your transdermal patch production needs. Consider partnering with a trusted converter early in the product development process so you can streamline manufacturing and achieve commercial production faster.

Are you looking to develop transdermal patches and expand your business? Contact The Tape Lab and put our knowledge and industry-leading capabilities to work for you.