During the first week of May (May 2-5), the Pressure Sensitive Tape Council (PSTC) held the inaugural PSTC Tape Week in Lake Buena Vista, Florida.

PSTC Tape Week is a lot more than a traditional networking exercise. The primary objective is to unite the Tape Manufacturers with the adhesive makers and engineers of the pressure-sensitive adhesive (PSA) industry under one roof. The focus is to enable niche-specific knowledge sharing and to provide segmented learning and growth opportunities for PSA professionals.

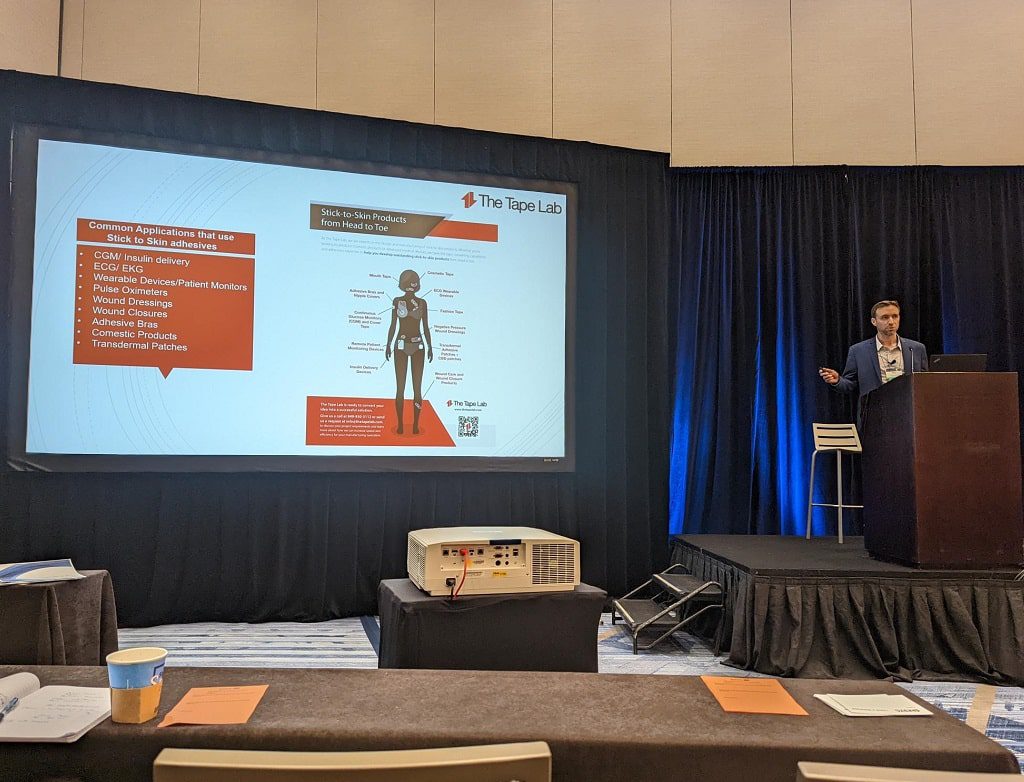

Our President, Jason Zajac had the honor to speak on the medical stick to skin pressure-sensitive adhesives (PSAs) and what trends will shape the medical market, more specifically the wearables space in the near to medium-term future.

Let’s explore further.

PSTC – Shaping The American Tape Manufacturing Industry

For the past 60 years, the Pressure Sensitive Tape Council (PSTC) has dedicated its resources to developing a thriving tape manufacturing sector within the United States. It strives to create an enabling environment for North American tape manufacturers and affiliate suppliers, thereby, helping them produce quality pressure-sensitive adhesive tape products in the global marketplace.

Jason Sketches A Thorough Overview Of The Medical Stick-to-Skin Industry

After touching upon common stick-to-skin adhesive applications, Jason elaborated on the core deciding factors while choosing the right PSA and ended by shedding light on the importance of choosing the right converting partner. Let’s dive a bit deeper into each section:

- Common Stick-To-Skin Applications: Wearable stick-to-skin products give doctors the freedom to become time and location-independent. Healthcare providers can effortlessly gather vital patient information and take appropriate action from virtually anywhere. More importantly, they offer numerous application options from head to toe including CGM/insulin delivery, ECG/EKG, wearable devices/patient monitors, pulse oximeters, wound dressings, wound closures, adhesive bras, cosmetic products, and transdermal patches.

- Factors For Determining What PSA To Use: The factors that dictate which medical PSA should be chosen include:

- Wear Time: Depending on the patient’s needs, stick-to-skin products can be worn anywhere for a couple of days to several weeks. For short-term usage, the core adhesive components are silicones, rubbers, hydrogels, and hydrocolloids. And the backing should be foams, TPE, PE film, and PET. Stick-to-product intended for long-term use should have adhesives made from solvent acrylics and UV cured acrylics. And the backings should either be PU film or non-woven PET/ PU.

- Moisture Management: Stick-to-skin devices are designed to be compatible with the user’s daily lifestyle. That means it must stand up to sweat, bodily fluids, and external moisture. For enhanced absorption hydrocolloids and absorbent foams should be utilized. And when it comes to breathability, materials such as PU film backings, non-woven backings, and perforated PSAs have consistently delivered the desired results.

- Skin Irritation: The slightest irritation can compel the wearer to abandon the device, thereby, defeating its entire purpose. Factors such as the wearer’s age, local climate, daily activity volume, device placement on the body and product wear time all equally impact the irritation level. Adhesive materials such as acrylic, rubber, silicone, and hydrogels offer the right balance for eliminating irritation. For the backing, the preferred material choices are PU/ PET/ PE film, on-wovens, PE Foams , and cloth.

- Clarity of backing Material & PSA: Backing is the carrier to which the PSA layer is laminated. Moreover, it dictates the way the tape behaves and ensures that the skin has breathability. Applications include wound dressings, NPWT, cover tapes, and shower tapes. Materials such as PU film, PET film, and PE films are used for an optically clear backing.

- Material Availability & Strong Supplier Partnerships: What sets The Tape Lab apart is its rock-solid supply chain. We enjoy strong relationships with leading material manufacturers in the medical adhesive space. Our partners include 3M, Avery Dennison, Berry Plastics, Adhesive Applications and Polymer Science. This ensures immediate material access and enables us to design and produce customized medical adhesive solutions far quicker and cheaper than most of our competitors.

- The Right Conversion Partner: No business, healthcare, or otherwise can survive without undisputed integrity. The easiest way to ensure that is by choosing a seasoned material converting partner that brings to the table extensive research and development capabilities. The Tape Lab checks all of these boxes:

- Unquestionable Credibility & Extensive Adhesive-Specific Experience: The Tape Lab has over 18 years of research & manufacturing experience in the stick-to-skin medical tech space. Some of the largest names in the industry have entrusted us with developing adhesive solutions for their flagship continuous health monitors. We’re supremely confident we can meet and exceed your expectations as well.

- A Wide Range OF Stick-To-Skin Products: The Tape Lab currently offers 11 individual categories for stick-to-skin products and 6 categories for wearable medical products. Our range includes but is not limited to adhesive bras, boob tape, CBD adhesive patches, fashion tape, wearable device tape, and diagnostic tape. You can explore our full product range over here. No matter what you have in mind, you’ll find it under one roof with The Tape Lab.

- The Ability To Customize & Unrivaled Engineering Expertise: The Tape Lab excels in every facet of medical adhesive design and manufacturing. Our core competencies include designing the tapes, die-cutting the patches, layer lamination, customizing the liner releases, and full-service OEM assembly. This gives us the scale and production capacity that will empower you to bring your product to market quicker and cheaper than your competition.

Next Step – Book A Free Consultation

Looking for a full-service tape converter and adhesives specialist? Contact The Tape Lab today. Our experts will schedule an obligation-free call and explain how we can put our full suite of converting services to work for you.