The landscape of health monitoring is evolving rapidly, and the recent announcement from industry giants like Dexcom and Abbott about launching over-the-counter continuous glucose monitors (CGMs) marks a significant milestone. These innovations promise to broaden access to technology that has already revolutionized diabetes care, bringing millions of new users—those with prediabetes, type 2 diabetes, and even health-conscious individuals—into the fold.

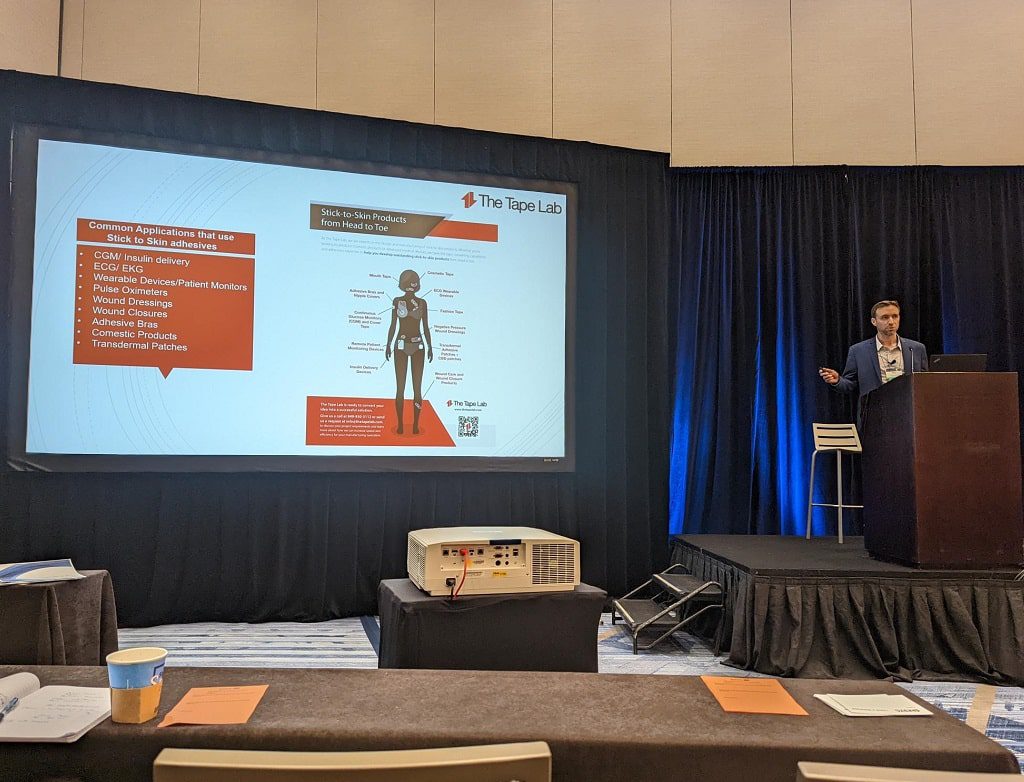

At The Tape Lab, we understand that while these advancements open up incredible opportunities, they also introduce new challenges, particularly in the realm of long-term device adhesion. As CGMs become a staple in preventive health, the demand for reliable, comfortable, and skin-friendly adhesive solutions is more critical than ever.

Why Adhesive Expertise is Crucial for CGM Success

The efficacy of CGMs hinges not just on their ability to deliver accurate data but also on their capacity to stay securely attached to the user’s skin under varying conditions. This is where our specialized adhesive solutions come into play. We’ve observed firsthand how issues like skin irritation, device dislodgement during exercise, and adhesive failure in humid environments can undermine the utility of wearable devices. At The Tape Lab, our mission is to preempt these challenges with adhesives that offer both strength and comfort, ensuring that CGMs perform optimally, whether worn by an active individual or someone with sensitive skin.

Real-World Testing: The Tape Lab Difference

Transitioning CGMs to over-the-counter products means they’ll be used by a broader audience, many of whom might be new to such technology. Therefore, the importance of rigorous real-world testing cannot be overstated. At The Tape Lab, we go beyond laboratory conditions, subjecting our adhesive solutions to the kind of everyday scenarios that users encounter. From enduring the friction of a seatbelt to withstanding long hours in a high-humidity environment, our adhesives are engineered to meet and exceed the demands of real life.

As the healthcare industry embraces this new era of accessible remote health monitoring, The Tape Lab is proud to support this transition with adhesive solutions designed to keep wearables secure, comfortable, and effective for all users. We are excited to be part of this journey toward better health outcomes through innovative technology.

Join the Technological Movement

Now is the time to stay ahead of the curve and discover adhesive solutions for the latest medical technology and wearable devices. Work with our experts to determine the right solution for your product.