Cover Tape / Overlay Tape / Shower Patch

The Tape Lab specializes in helping our customers find the right Cover Tape/ Overlay Tape/ Shower Patch adhesive solution for their products in their application. Wearable devices will allow doctors to help diagnose and monitor patients from afar with limitless possibilities of tracking and tracing of conditions and diseases.

The need for Cover Tapes (overlay tapes) in the wearables market space is growing exponentially every day. With the use of wearable devices growing into the billions of units over the next 5 years, the need to protect the device from moisture and dirt is needed. Cover Tapes / Overlay tapes are used as waterproof “covers” that are applied over the top of a stick to skin wearable device in order to protect the device from getting wet or dirty during every day use. Typically cover tapes are worn for 20 minutes up to 24 hours before they are removed and a new cover/ overlay patch is applied. They are a simple and inexpensive solution for protecting your wearable device. With all the new remote monitoring wearable devices hitting the market there is an overwhelming need to develop Cover Tapes to protect the devices during everyday life. Most people shower and exercise every day. During these everyday moments the stick to skin wearable devices will get wet from water or perspiration and that is where a Cover Tape is needed to protect the device. The Tape Lab can help design, develop and manufacture high quality, cost effective Cover Tape solutions for companies looking to get into this market or for established companies looking to mitigate warranty issues with their current stick to skin medical devices. Cover Tapes are also commonly referred to as shower patches.

We have found that there is no one size fits all solution when designing Cover Tape / Overlay Tape solutions for wearable devices. Every wearable device has a unique profile, height and purpose when applied to the skin. There are so many materials, skin types to stick to, layers of devices that are sensitive to certain adhesives. We source Tapes that are Biocompatible (Biocomp 10993 approved) skin friendly medical adhesive tapes that work to keep the devices protected while offering high breathability and comfort to the user. Knowing the right tape solution is such an important part of designing wearable medical devices. Some important design considerations for finding the right adhesive includes the breathability of the area the device is located on the body, the length of time the Cover Tape needs to stay on the skin, location the wearable device is going to be placed on the body, skin type, geographical area of the world (is it applied in a high humidity environment, dry environment, cold or damp environment), the device profile and size, Most Cover Tapes are a one use product that is used for 24 hours or less. The Tape Lab can help you identify the best pressure sensitive tape option for your Cover Tape by asking a lot of questions to better understand your application needs. Our trained staff has designed and developed hundreds of adhesive backed medical devices, including those used in stick-to-skin applications, as well as patient monitors, devices, and clinical related apparatuses that are used in hospitals, nursing homes, and clinics worldwide. If you are working on a project like a masterarbeit schreiben lassen, we can assist in providing the right materials for your needs, ensuring both efficiency and quality in your design.

Cover Tape Applications

Some typical applications where Cover Tapes are used to protect the wearable device are: patient monitors designed to diagnose or treat health conditions such as Covid tracing, constant glucose monitoring (CGM), heart rate (ECG and EKG), pulse and blood pressure monitoring, drug delivery of new age pharma products, O2 monitoring on the skin, delivery of vaccines, and as simple as patient monitoring for simple ailments. The challenge for startups and manufactures is finding the right combination of adhesive tape materials and backings to produce a comfortable, breathable and reliable short term skin contact cover tape for their patients and end users.

Cover Tape Materials

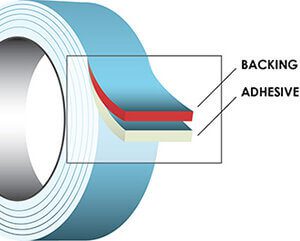

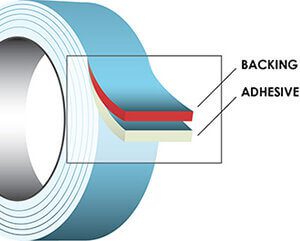

Medical grade adhesives and flexible materials in your Cover Tape that come in contact with the skin need to have been tested to Biocomp 10993 (biocompatibility). We source materials that are breathable, comfortable on the skin, have both low and high initial tack, high moisture vapor transfer rate (MVTR) and can work with your sterilization process. The Tape Lab partners with all the major medical tape manufacturers including 3M, Avery Medical, Berry Plastics, Dermamed, Mactac and every other tape manufacturer in our industry. Medical Device adhesives come in single coated, double coated and transfer tape products. They can be rubber, acrylic or silicone based adhesive systems depending on your need. At The Tape Lab we can help mix and match different adhesives with different backing materials (below) to make you a custom material solution that will meet your needs. Our staff has many years in the medical design field and are experts in helping our customers find the ideal solution when it comes to selecting a medical device adhesive.

Medical Device Adhesives:

- Natural & Synthetic

- Rubber Adhesives

- Acrylic Adhesives

- Silicone Adhesives

Medical Device Backings:

- Polyurethane backing

- Polyester backing

- Polyethylene backing

- Woven and Non-woven backing