In the fast-paced realm of innovation, a new trend is emerging that promises to redefine the way we interact with wearable health monitoring devices: adhesive technology. Gone are the days of bulky gadgets strapped to our wrists or clipped onto our clothes; adhesive wearables are discreet, flexible, and effortlessly blend into our everyday lives. Let’s dive into the fascinating world of adhesive wearables and explore how they’re revolutionizing industries in ways we never imagined.

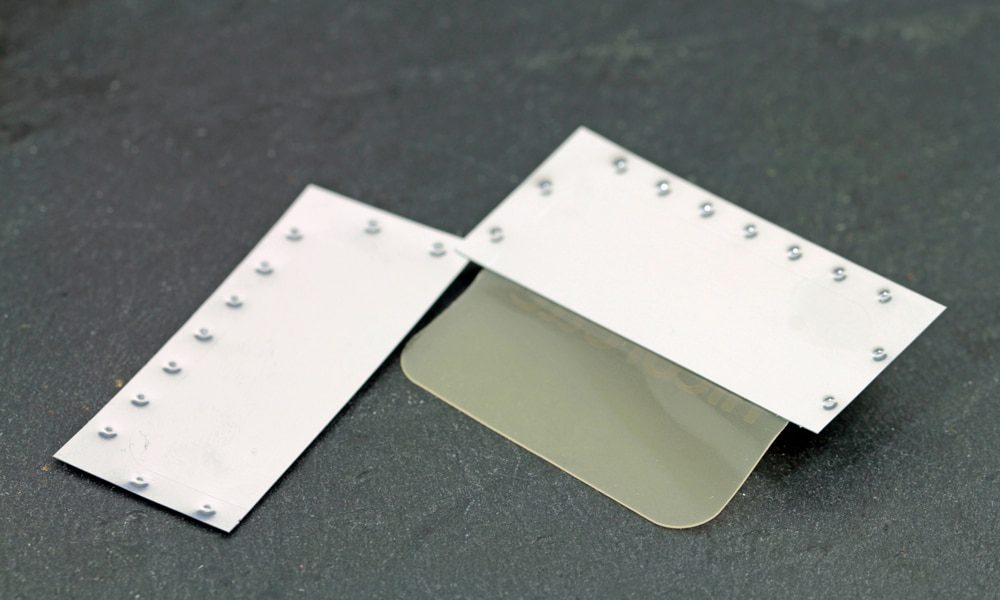

At the heart of adhesive wearables lies a simple yet ingenious concept: technology that sticks. These devices are equipped with sensors, microchips, and other electronic components, all nestled within a thin, flexible substrate that adheres directly to the skin. This design not only ensures a snug and comfortable fit but also allows for continuous monitoring and data collection without the need for cumbersome accessories.

Healthcare is perhaps the most promising frontier for wearables that stay with tape. Imagine a future where patients no longer need to be tethered to bulky monitoring equipment during their hospital stay. With adhesive wearables, medical professionals can remotely monitor vital signs, track medication adherence, and even detect early signs of deterioration in real-time, all while patients go about their daily activities unhindered.

How Different Conditions Use Wearable Devices for Monitoring Health

Wearable health monitoring devices have the potential to benefit individuals living with various diseases and conditions by providing continuous, real-time data monitoring and analysis. Here are some examples of diseases and conditions that can benefit from wearable health monitoring devices:

- Diabetes: Wearable devices equipped with glucose sensors can monitor blood sugar levels continuously, allowing diabetic individuals to manage their condition more effectively. These devices can provide alerts for high or low blood sugar levels, helping users take timely action to prevent complications.

- Heart Disease: Wearable devices can monitor heart rate, rhythm, and activity levels, providing valuable insights into cardiovascular health. For individuals with heart disease or at risk of heart conditions, continuous monitoring can help detect irregularities early and facilitate timely intervention.

- Hypertension (High Blood Pressure): Wearable blood pressure monitors can track blood pressure levels throughout the day, providing a more comprehensive picture of cardiovascular health. This continuous monitoring can help individuals and healthcare providers identify trends, optimize treatment plans, and make lifestyle modifications as needed.

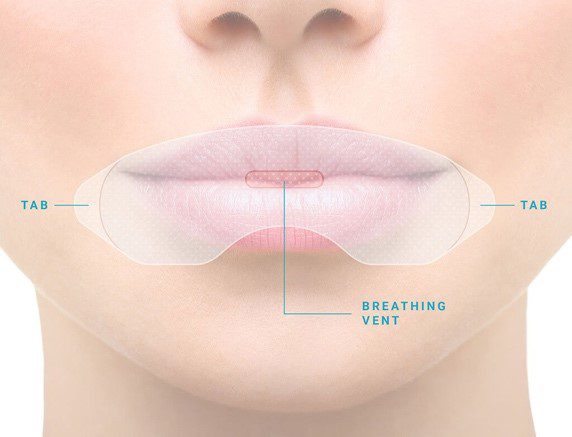

- Sleep Disorders: Wearable devices equipped with sleep tracking capabilities can monitor sleep patterns, duration, and quality. For individuals with sleep disorders such as insomnia or sleep apnea, these devices can provide insights into sleep disturbances, facilitating diagnosis and treatment optimization.

- Chronic Respiratory Conditions: Wearable devices can monitor respiratory rate, lung function, and oxygen saturation levels, providing valuable data for individuals with chronic respiratory conditions such as asthma, chronic obstructive pulmonary disease (COPD), or cystic fibrosis. Continuous monitoring can help detect exacerbations early and guide treatment decisions.

- Epilepsy: Wearable devices equipped with motion sensors can detect seizure-like movements and alert caregivers or emergency contacts in real-time. These devices can provide peace of mind for individuals with epilepsy and their loved ones, enabling prompt assistance during seizure events.

- Chronic Pain Management: Wearable devices can track activity levels, movement patterns, and physiological signals associated with pain, providing insights into pain severity and triggers. For individuals living with chronic pain conditions such as fibromyalgia or arthritis, these devices can facilitate self-management strategies and optimize pain management interventions.

- Mental Health Conditions: Wearable devices can monitor physiological indicators of stress, anxiety, and mood fluctuations, providing individuals and healthcare providers with insights into mental health status. Continuous monitoring can help identify patterns, triggers, and early signs of mental health relapse, enabling timely interventions and support.

- Parkinson’s Disease: Wearable devices can monitor movement patterns, tremors, and gait abnormalities associated with Parkinson’s disease, providing valuable data for disease management and treatment optimization. These devices can assist healthcare providers in monitoring disease progression and adjusting medication regimens accordingly.

- Stroke Rehabilitation: Wearable devices can track movement, activity levels, and rehabilitation progress following a stroke, providing objective data for therapy planning and monitoring. These devices can help individuals and healthcare providers track recovery milestones, optimize rehabilitation programs, and facilitate long-term recovery.

Overall, wearable health monitoring devices have the potential to revolutionize disease management and healthcare delivery by providing continuous, personalized monitoring and support for individuals living with various diseases and conditions. As technology continues to advance, these devices hold promise for improving outcomes, enhancing quality of life, and empowering individuals to take an active role in their health and well-being.

Get a Custom Solution Created for Your Business

At The Tape Lab, we’re not just creating wearable device adhesives; we’re crafting partnerships to bring your custom innovations to life. We design, manufacture, and transform adhesives into personalized solutions.

Already have an idea of what you need? Want to pick the brain of an expert? Contact The Tape Lab and let’s combine your vision with our knowledge and industry-leading capabilities to create a custom adhesive solution.