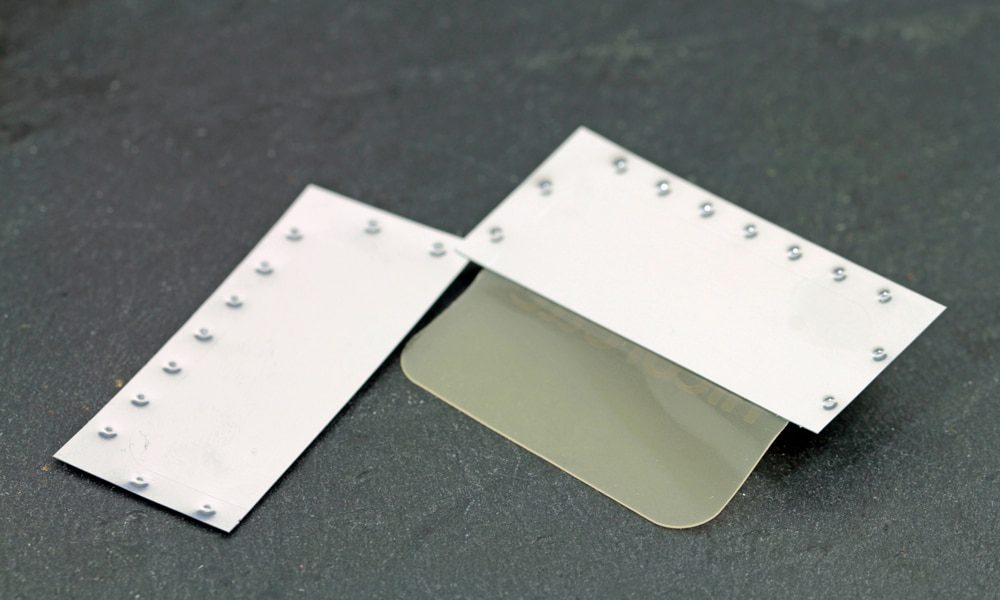

Manufacturing transdermal patches can be a valuable way for cosmetics, health and wellness brands to expand product lines, enter new markets and reach more customers. We know because we help many of our partners do just that, delivering end-to-end manufacturing and converting solutions for formulating, designing, producing and packaging transdermal patch products. But in talking with people in our industry, we also hear a lot of misconceptions about what it takes to create these products — or whether it’s even worth it. From CBD patches to B12 patches, pain relief products to sleep aids and everything in between, some manufacturers are unsure about the viability of bringing these products to market. So, we thought we’d use our experience to dispel some common myths about manufacturing transdermal patches.

Myth #1: The market is already oversaturated with CBD patches and other transdermal products

Truth: There is still ample opportunity for manufacturers to make an impact and capture market share for a variety of transdermal patch products. In total, the U.S. market for transdermal patches in 2020 was estimated at around $17.6 billion. Some experts project that to grow to around $30.5 billion by 2026. When thinking about CBD patches specifically, some organizations predict the U.S. market for CBD products will hit $6 billion by 2025, while others project it to hit $20 billion by 2024. So, it’s clear there is a lot of room to grow in this space, and a lot of demand that will need to be met. Brands and manufacturers that can establish product lines now will be in a better position to grow alongside the overall market.

Myth #2: Ambiguous laws and regulations for manufacturing CBD patches make the idea too risky

Truth: It is possible to manufacture CBD patches and other therapeutic products without putting your company in legal jeopardy. Yes, there was a time early in the CBD craze where governmental bodies were scrambling to enact new laws, resulting in a patchwork of regulations. Although CBD laws and regulations continue to evolve, there is much less gray area than there once was and legal resources are much more familiar with manufacturing rules and registration requirements for producers of cannabis-derived products. The FDA also has clear guidance on what is legal to put into formulations for transdermal absorption. Any brand or manufacturer looking to get into this space should still consult their legal counsel. But starting to create these products is not the venture into the wilderness it once was. Brands that partner with a reliable converter can feel confident they will stay compliant and produce products consumers will love.

Myth #3: Adhesive converters shy away from working with transdermal materials, including CBD

Truth: There are many adhesive converters — including The Tape Lab — that are ready and willing to take on any transdermal patch manufacturing project. Sure, some companies may not have the experience or expertise to reliably deliver these types of products. But others have been doing it for years and can create transdermal patches that meet exact dosage and quality standards in every production run. Partnering with a trusted converter that has a proven track record of manufacturing transdermal patches can help keep production costs in check by streamlining the development process, ultimately helping you bring products to market faster.

Myth #4: Customers don’t want patches, they want other forms of CBD

Truth: Patches have carved out their own space in the CBD market alongside gummies, oils and other products. In fact, “topicals” as a product category currently dominate the U.S. CBD market, making up around 50% of all CBD products sold. One survey found that 8% of CBD users are interested in patches specifically, while another 8% are interested in skin care products, 12% in soaps and 18% in topical sprays. So, consumers are already on board with transdermal absorption as a transmission method, and patches can be a great option for timed or slow-release products. As more patches become available to consumers, preferences are likely to change. The key is to make sure any stick-to-skin product is comfortable, breathable and doesn’t irritate or damage the skin. By prioritizing the wearer’s experience, manufacturers can create transdermal patch products that users love and want to use.

Myth #5: Plant-based transdermal patches are too difficult to manufacture to be cost-effective

Truth: Transdermal patches are a viable product when producing them with the right partner. Sure, from a design and production standpoint, plant-based transdermal patches are more complex than a label or sticker. But the challenge is far from insurmountable. Experienced adhesive converters can fall back on knowledge gained from past projects to speed product development, using tried-and-true materials and production methods to streamline operations. Essentially, a converter partner can tweak established designs to infuse high-quality materials with your unique therapeutic formulation and create new products that stand out in the market. By finding the right partner rather than starting from scratch, you can achieve cost-effective manufacturing that moves your business forward.

Interested in learning more about manufacturing transdermal patches? Contact The Tape Lab today to see how our private labeling services can help you get products into market quickly and on-budget.