In the realm of medical devices, adhesives are the unsung heroes, ensuring that devices adhere securely to the skin, wounds heal effectively, and components stay in place during medical procedures. From wound care to wearable sensors, the right medical adhesive according to the specific application is crucial for proper functionality, security, and patient comfort. Let’s dive into the diverse world of adhesives used in medical devices, exploring the different adhesive materials, applications, and key considerations.

Acrylic Adhesives

Acrylic adhesives are versatile and known for their durability and resistance to environmental factors.

- Applications: Used in medical tape, wound dressings, and long-term wearables.

- Features: Offers strong bonding and long-term adhesion.

Rubber Adhesives

Rubber adhesives are versatile and known for their quick stick properties and adherence to low surface energy materials, as well as skin.

- Applications: Used in medical tape, wound dressings, and short-term wearables, tie layers in wearable devices.

- Features: Offers strong bonding and shorter-term adhesion on skin.

Silicone Adhesives

Silicone adhesives are biocompatible and flexible, making them suitable for skin contact applications.

- Applications: Commonly used in wound dressings, medical tapes, and devices requiring gentle skin adhesion.

- Features: Provides a comfortable and effective bonding solution for sensitive skin.

Hydrocolloid Adhesives

Hydrocolloid adhesives create a moist environment for wound healing and are commonly used in wound care applications.

- Applications: Found in wound dressings, bandages, and patches for managing exudate.

- Features: Promotes healing and provides a barrier against external contaminants.

Polyurethane Adhesives

Polyurethane adhesives offer high strength and flexibility, making them suitable for medical tubing and catheters.

- Applications: Used in medical devices that require a strong yet conformable bond.

- Features: Resistant to water and chemicals, ensuring stability in various medical environments.

Water-Resistant Adhesives

Water-resistant adhesives are crucial for wearable health technology intended for activities like swimming or intense workouts.

- Applications: Used in waterproof fitness trackers, smartwatches, and other wearables exposed to moisture.

- Features: Maintains adhesion even in wet conditions.

Cloth & Fabric Adhesives

Fabric adhesives provide comfort and breathability, making them suitable for wearables requiring continuous skin contact.

- Applications: Used in health monitoring patches and devices where user comfort is a priority.

- Features: Skin-friendly, allows air circulation.

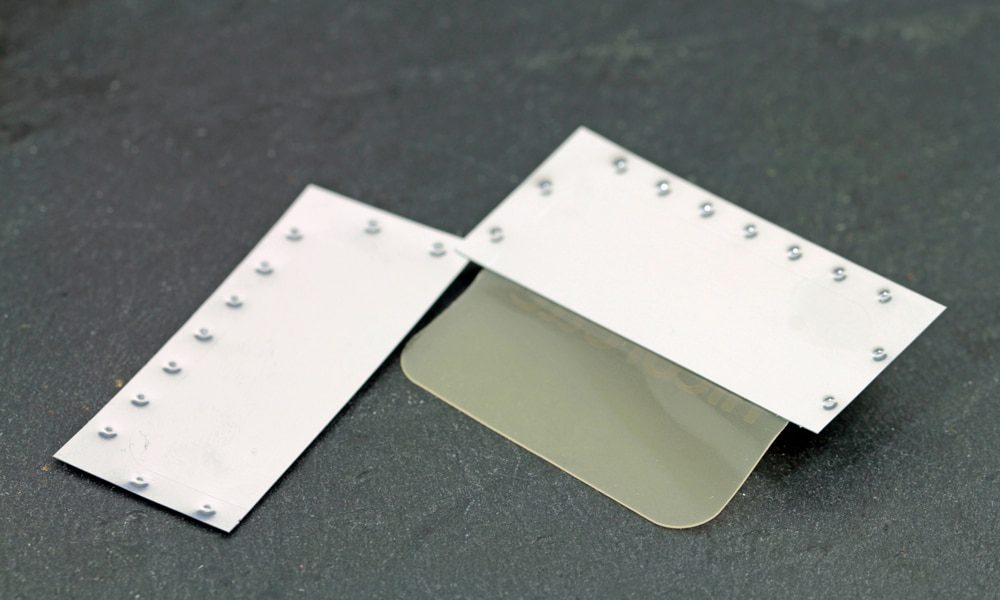

Double-Sided Adhesives

Some wearables require adhesives on both sides for increased stability.

- Applications: Used in wearables that need to adhere to both the skin and the device surface simultaneously.

- Features: Ensures a secure attachment, preventing device shifting.

Transparent Adhesives

Transparent adhesives are ideal for wearables where aesthetics and discreteness are important.

- Applications: Used in wearables that need to blend seamlessly with the user’s skin.

- Features: Allows for easy monitoring of the skin under the adhesive.

Get Customized Adhesives for Your Medical Device

As technology advances and patient needs evolve, the development of specialized adhesives continues to contribute significantly to the field of medical innovation. The careful selection of the right adhesive is paramount, considering factors such as biocompatibility, strength, and intended application, to ensure the seamless integration of medical devices into patient care.

Contact us to learn more about how we can help support your creation of the next medical device.