The Evolution of Medical Tapes in Wearable Technology

The landscape of wearable medical devices has transformed dramatically in recent years, driven by advancements in telehealth and remote patient monitoring. This evolution has placed new demands on the humble medical tape, requiring it to do more than ever before. The Tape Lab specializes in engineering medical tapes that meet the unique demands of wearable devices, from ensuring long-term adhesion to accommodating the flexibility needed for patient comfort.

As wearable technology becomes more sophisticated, so too must the tapes that secure these devices to the skin. We’re not just talking about simple bandages anymore; modern medical tapes must contend with challenges like:

- Varying skin types and conditions

- Extended wear times

- Exposure to moisture and temperature fluctuations

- The need for breathability to maintain skin health

- Compatibility with device electronics and sensors

Our engineering process takes all these factors into account, resulting in tape solutions that are as advanced as the devices they support.

Engineering Precision: The Science Behind Medical Adhesive Tape

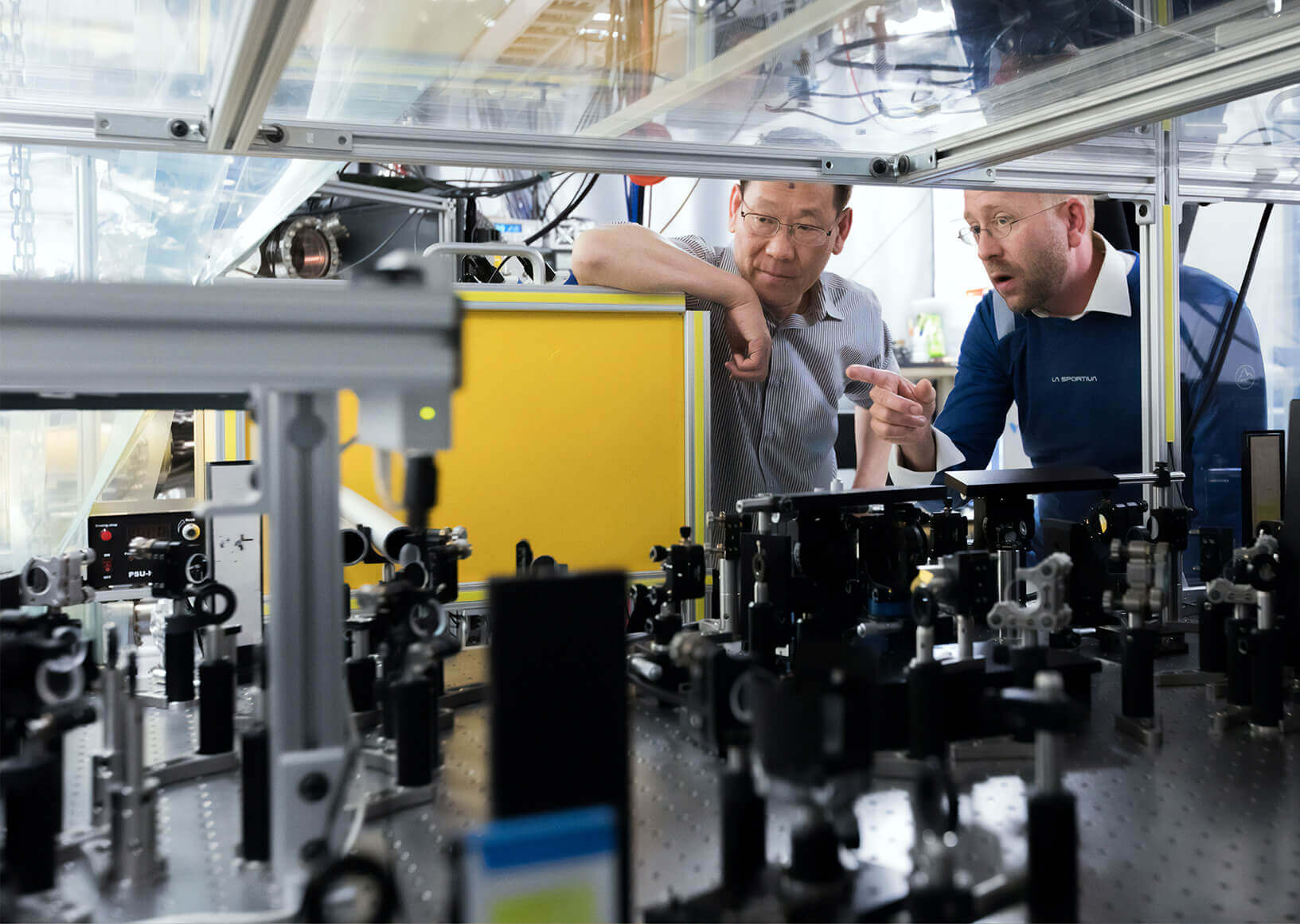

At The Tape Lab, we understand that the success of a wearable medical device often hinges on the quality and specificity of its adhesive components. Our expertise in medical adhesive tape engineering ensures optimal performance and patient comfort in wearable applications. But what sets our approach apart?

- Material Selection: We work with a variety of backing materials, including polyurethane, polyester, and polyethylene, each chosen for its unique properties that match specific device requirements.

- Adhesive Formulation: While we don’t create the adhesives ourselves, we partner with industry leaders like 3M, Avery Medical, and Berry Plastics to source the perfect adhesive for each application.

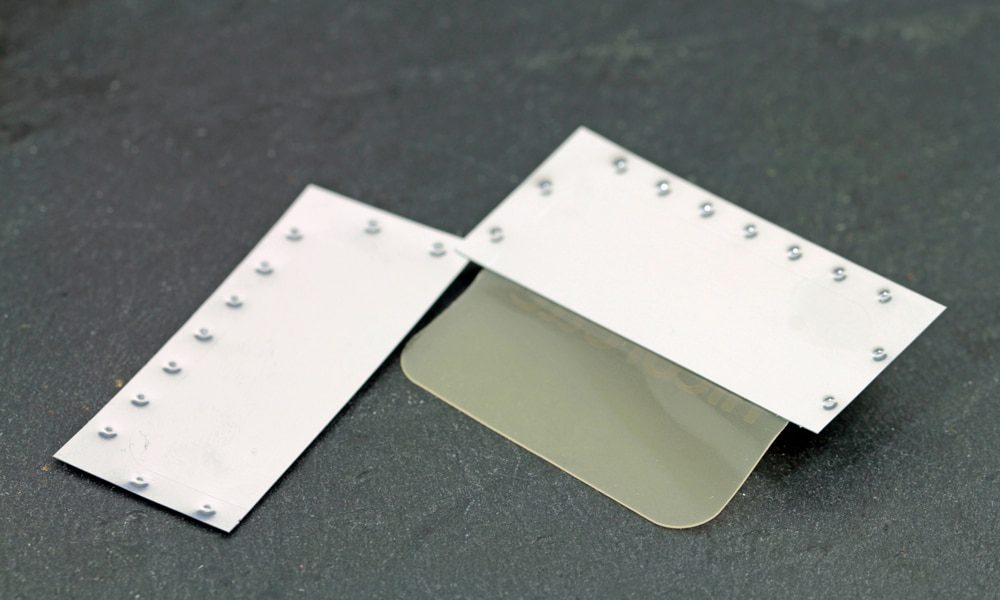

- Custom Converting: Our state-of-the-art converting services, including die cutting, laminating, and printing, allow us to create tape solutions that fit precise specifications.

- Clean Room Manufacturing: Our ISO 8 clean room ensures that every tape product meets the highest standards of cleanliness and quality control.

This combination of material expertise, strategic partnerships, and advanced manufacturing capabilities allows us to engineer medical adhesive tapes that stand up to the rigorous demands of wearable devices.

Optimizing Medical Device Wearables with Custom-Engineered Tapes

The world of medical device wearables is incredibly diverse, ranging from simple activity trackers to complex drug delivery systems. Each device presents its own set of challenges when it comes to adhesion, and that’s where our custom engineering approach shines.

We collaborate with leading manufacturers to create custom tape solutions for cutting-edge medical device wearables. Our process involves:

- Consultation: We work closely with device manufacturers to understand the specific requirements of their product.

- Design: Our engineering team develops custom tape designs that address the unique challenges of each device.

- Prototyping: We create and test prototypes to ensure the tape solution meets all performance criteria.

- Production: Once approved, we manufacture the custom tape solution in our clean room facility.

This tailored approach ensures that each wearable device benefits from a tape solution that’s optimized for its specific use case, whether it’s a long-term wear cardiac monitor or a disposable glucose sensor.

Challenges and Solutions in Tape Engineering for Wearable Medical Devices

The success of wearable medical devices often hinges on the quality and specificity of their adhesive components. Some of the key challenges we address include:

- Skin Sensitivity: We select materials that minimize the risk of irritation, even with prolonged wear.

- Moisture Management: Our engineered tapes often incorporate breathable materials that allow moisture to escape while maintaining a secure bond.

- Flexibility: We design tapes that move with the body, ensuring comfort without compromising adhesion.

- Electronics Integration: For devices with onboard electronics, we engineer tapes that accommodate components like batteries and sensors without interfering with their function.

By addressing these challenges head-on, we help our clients create wearable devices that are not only effective but also comfortable and reliable for patients.

The Importance of Medical Grade Adhesive Tape in Device Performance

When it comes to wearable medical devices, not just any tape will do. Our medical grade adhesive tape undergoes rigorous testing to ensure biocompatibility and long-term reliability. This level of quality is crucial for several reasons:

- Patient Safety: Medical grade tapes are designed to minimize the risk of skin irritation or allergic reactions.

- Regulatory Compliance: Our tapes meet stringent industry standards, helping device manufacturers navigate the complex landscape of medical device regulations.

- Device Longevity: High-quality medical grade tapes ensure that devices stay in place for their intended wear time, improving data collection and treatment efficacy.

By focusing on medical grade adhesive tapes, we help our clients create devices that not only perform well but also meet the high standards expected in the healthcare industry.

The Future of Medical Tape Engineering

As wearable technology continues to advance, so too will the demands placed on medical tapes. At The Tape Lab, we’re always looking ahead, anticipating the needs of tomorrow’s medical devices. Some areas we’re exploring include:

- Smart Adhesives: Tapes that can respond to changes in the wearer’s skin condition or environment.

- Biodegradable Options: Environmentally friendly tapes for short-term use devices.

- Enhanced Sensor Integration: Tapes designed to work seamlessly with next-generation biometric sensors.

Our commitment to innovation ensures that we’ll continue to provide cutting-edge tape solutions as the wearable medical device market evolves.

Partnering with The Tape Lab for Your Wearable Device Needs

In the world of wearable medical devices, the right tape can make all the difference. At The Tape Lab, we bring together material science, engineering expertise, and a deep understanding of the medical device industry to create tape solutions that enhance device performance and patient experience.

Whether you’re developing a new wearable device or looking to improve an existing one, we’re here to help. Our team of experts is ready to work with you to engineer the perfect tape solution for your unique needs.

Ready to take your wearable medical device to the next level? Contact The Tape Lab today to learn how our custom-engineered medical tapes can enhance your product’s performance and user experience.