Manufacturers in need of pressure-sensitive adhesive (PSA) tape converting services will find no shortage of partners ready to take on the job. There are thousands of tape converters across the country. This competition is good for manufacturers, but also makes it more difficult to sort through your options and choose the right partner for your business. It’s also not a decision to take lightly. Working with the wrong converter could significantly delay project timelines and increase costs. So, you need to do your due diligence. Here’s what to look for in a PSA tape converter to help ensure an efficient and timely custom manufacturing process.

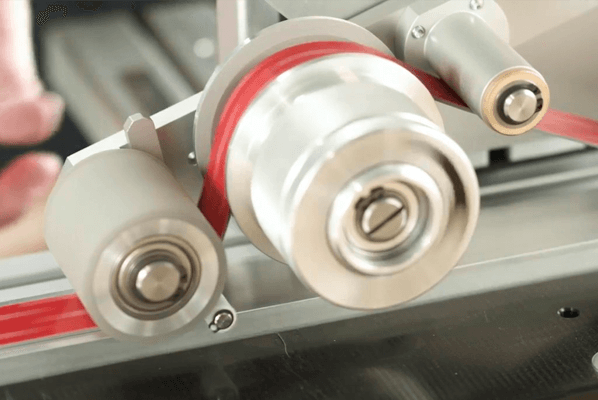

Technology behind the capabilities

Many PSA tape converting companies offer the same kinds of services: die cutting, slitting, rewinding, laminating, spooling, etc. So, the differentiator between prospective partners can come down to the technology they use to execute projects. Do they have the latest equipment? Do they have the machinery to offer a wide range of slitting options, or are options more limited? Can they provide a customer experience that supports how you do business? Technology investments can pay big dividends to manufacturers. So, ask first about capabilities, and then dive deeper to try and find the real difference between prospective converting partners.

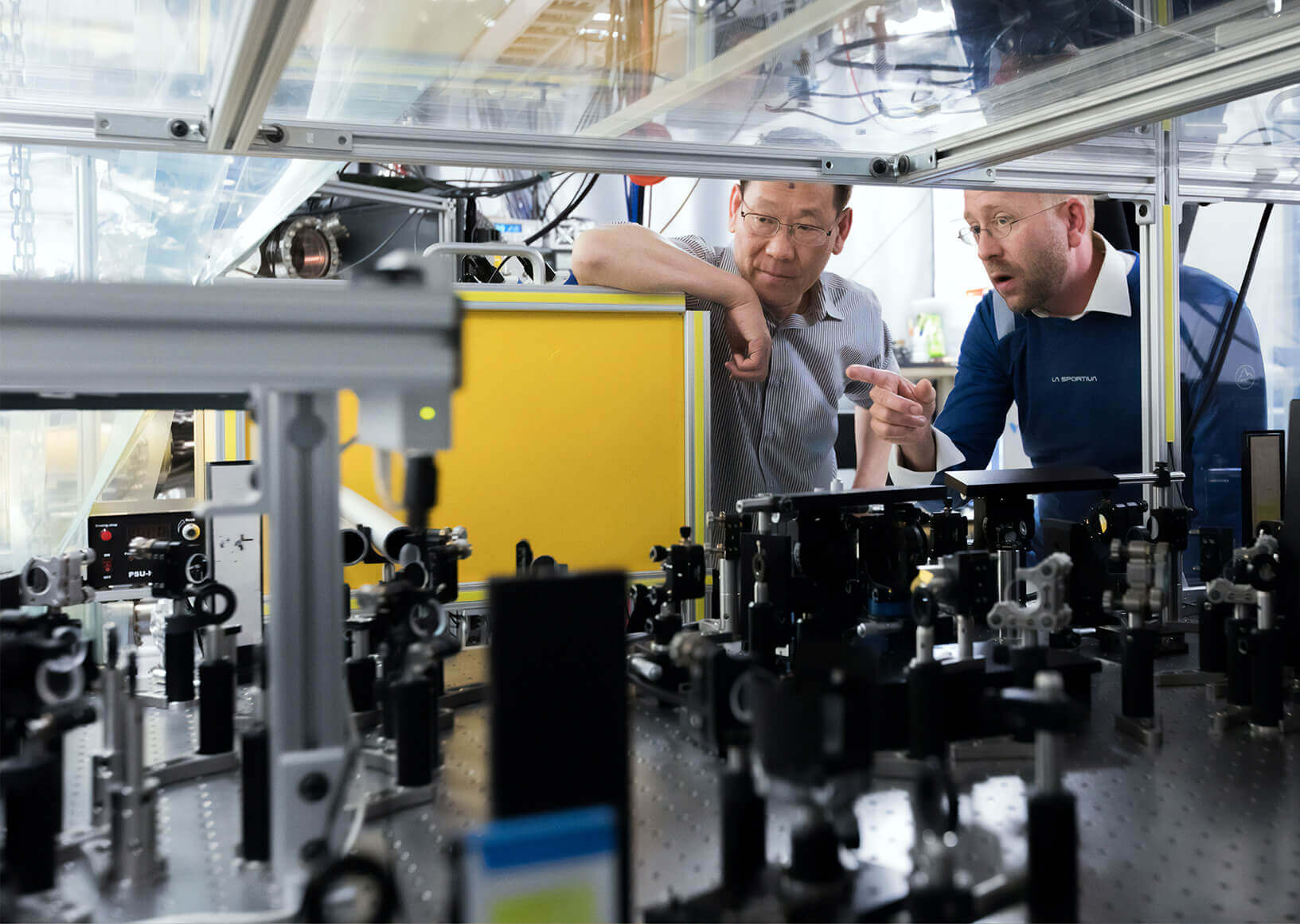

Experience and process

Perhaps more important than what technology a PSA tape converter uses is how they use that machinery. That means judging a potential partner’s experience and process. The value of an experienced converter goes beyond production costs. They can save you significant time and frustration by anticipating problems and devising solutions before issues occur. In terms of process, look for a converter that can provide end-to-end service, helping with every step from concepting to prototyping all the way through commercial production. Also, make sure the process they use complies with all industry standards for quality (more on that below) to reduce risk for your organization.

Supplier relations

At the end of the day, all the machinery and experience in the world won’t make a difference if the underlying materials in your product don’t meet requirements. That’s why it pays to work with a converter that can readily access a wide range of premium materials and tape products. For example, The Tape Lab is one of only a few companies in the converting industry with access to multiple 3M Preferred Converters, giving us unique access to industry-leading 3M products. This gives our customers greater flexibility in product design and helps avoid delays in the production process. In contacting adhesive converters, ask about their own partnerships and how they can leverage those relationships to support your business.

One-stop shop

A tape converting partner is supposed to make your life easier by providing services you don’t currently have in-house. But what if they could take even more off your plate? A converter that offers additional capabilities like tape printing, clean room manufacturing, packaging and fulfillment can be a one-stop shop for your entire project. Eliminating handoffs between contract manufacturers increases efficiency and speed to market while also simplifying project management. When talking with prospective partners about a specific capability or service, be sure to ask what else they offer. You may find ways to streamline your project and extract even more value from your converter partner.

Quality control certifications

Working with a new partner always introduces new risk, particularly when it comes to quality. Samples and case studies of past projects can only tell you so much. To feel more confident in your finished parts or products, look for quality control certifications. For example, if you are going to produce medical stick-to-skin devices, you will want to find a converting partner that is ISO 13485 certified. This means they follow strict industry standards and meet all compliance requirements. By refining your search only to converters like The Tape Lab that work with certified partners, you can reduce risk and feel more confident you made the right choice.

Comparing apples to apples

In searching for a new manufacturing partner, you’ll find that no two PSA tape converting companies are exactly alike. But you’re not comparing apples and oranges either. More like red apples and green apples. By knowing what to look for, you can easily compare vendors and find the ideal tape converter to move your business forward.

Looking for the perfect partner to help elevate your next project? Contact The Tape Lab and we’ll show you why we are uniquely suited to convert your ideas into solutions.