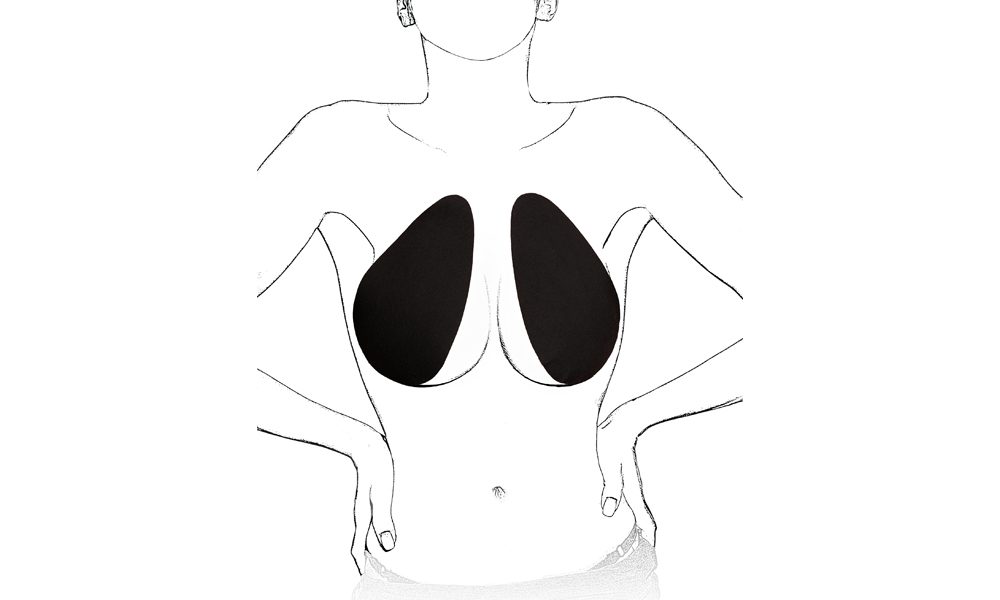

You don’t have to be a fashionista to know that the perfect outfit doesn’t happen by accident. There’s often a lot going on behind the scenes to create the right look. That’s why adhesive bras (boob tape), fashion tape and cosmetic tape products have become common not only for the fashion industry, but also for weddings, proms and everyday slaying. But just as it takes work to create the perfect ensemble, manufacturers of stick-to-skin fashion tape products know it’s equally difficult to create those products in the first place. Thankfully, that challenge becomes easier with the right tape converting partner. Here are five ways tape converters can use their connections, converting capabilities and engineering expertise to help brands create outstanding stick-to-skin fashion tape products.

1. Materials sourcing and on-time delivery

Spring and summer are right around the corner and manufacturers of fashion tape products know how important the wedding and prom seasons are for sales. Any delays in production — due to either operational inefficiency or supply chain issues — can cause brands to miss an entire season of sales. That’s why it’s so important for manufacturers to have partners they can depend on for reliable materials sourcing and timely delivery.

At The Tape Lab, we source our materials from a network of industry leaders to ensure we always have the raw materials necessary to convert stick-to-skin tapes and adhesives in a timely manner. We also have unique access to multiple 3M Preferred Converters, giving our clients unbeatable access to premium materials and tape products. With our strong connections to some of the biggest names in the industry, we are able to provide dependable on-time delivery so you can get products stocked in time for your busiest seasons.

2. Product development, engineering and design

Tape converters are experts in the science of pressure-sensitive adhesives and tape products. We can use our knowledge and experience to help you design and engineer stick-to-skin fashion tape products that meet strict requirements and ensure wearer comfort. We work in tandem with your design team and can offer guidance on materials selection and spot issues with product design before they impact production or performance. This helps streamline the entire product development process while reducing the burden on your internal teams.

If supply chain issues are causing persistent problems, we can even help you reformulate current products or design products to beat supply chain issues so your brand is less susceptible to disruption.

For more insights on creating successful stick-to-skin products, download our free ebook, Designing and Producing Wearable Stick-to-Skin Products.

3. Converting services streamline production

In addition to providing design expertise, a converter like The Tape Lab can also help streamline production using our full suite of converting services. We specialize in die cutting, laminating, sheeting, slitting, printing and more to make materials easier for your clients to apply, helping to ensure repeat customers. This helps speed production time and can improve cost efficiency throughout the production process.

4. Packaging and product fulfillment

As a full-service tape converter, The Tape Lab offers end-to-end assistance from product design all the way through packaging of finished products. We have the capabilities to take on small and large volume assembly, kitting and packaging to streamline the production process. Combined with our design and converting services, this creates a one-stop shop for brands that want a simple and efficient way to bring finished fashion tape products to market.

5. Fast, knowledgeable customer service

When product requirements or business needs change, you don’t want to be left on hold. A dedicated partner will be there to help troubleshoot problems and keep production on track with helpful and knowledgeable customer service. At The Tape Lab, you’ll be connected with an experienced designer who can help diagnose your issue and arrive at a solution quickly and efficiently. That kind of knowledgeable service can help reduce downtime, increase production efficiency and improve product performance.

The value of tape converters

The fashion industry moves quickly and styles are constantly changing. But one thing that doesn’t change is the value of reliable partnerships. By working with a trusted tape converter like The Tape Lab, you can become more agile, create better products and streamline your manufacturing process with expert engineering insights and tape converting services.

If you are looking to create better fashion tape products more efficiently, contact us today and we’ll show you how our tape converting services can bring exceptional value to your product development and manufacturing processes.