Die Cutting

The Tape Lab has the expertise in die-cutting and the capabilities of processing materials, including fabrics, films, foils, foams and other substrates with or without adhesive backings. We can die-cut any non-metalized material in roll form to make any conceivable shapes or sizes of flexible parts.

The Tape Lab offers parts as single individual pieces or finished parts on rolls or finished parts on sheets. We also offer simple perforations to multi-layer die cuts with registration or island placement. We will customize your die cut to your specifications and tight tolerances. Custom die cut parts are used in a variety of applications including medical, industrial and stick to skin applications. Die cutting of tapes and flexible materials can usually reduce material waste, help with labor savings and assembly time and ensure a more precision finished product.

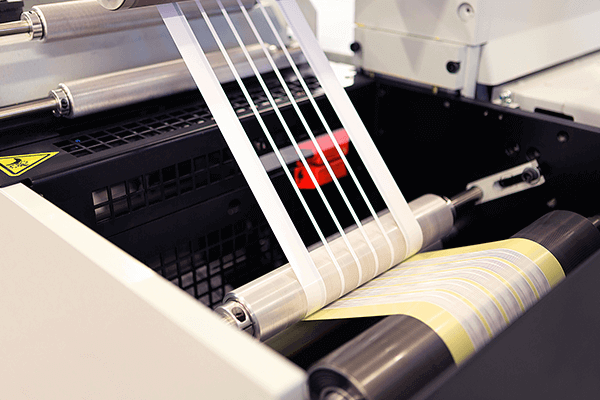

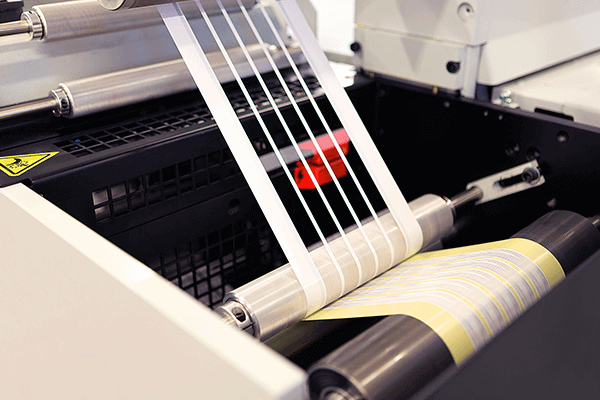

Die Cut Methods

We provide rotary die cutting, laser die cutting and steel rule die cuttings. Each method of die cutting is determined by the material, tolerance and quantity needed. Typically, flatbed die cutting is a great way to cut shapes through extremely dense or thick materias. A lot of time these materials are supplied in sheeted form. Rotary die cutting is a process in which materials in a roll form are fed through a press containing multiple die stations. Rotary die cutting allows The Tape Lab to laminate, slit and die cut all in-line to hold tight tolerances and bring multiple flexible materials together to make a finished product.

Some of our methods of die cutting include:

- Kiss cutting or butt cutting

- Cut through materials, also referred to metal to metal cutting

Die Cut Applications

Wearable Tape

The Tape Lab specializes in die cutting intricate wearable adhesive parts that help mount biosensors to the body. Many of these applications require The Tape Lab to laminate a single coated medical grade tape to a double sided tape that is island placed on top of the single coated tape. The double coated tape is the bonding layer that holds the device to the top of the medical grade tape. These applications are typically seen for CGM (constant glucose monitoring), health and fitness trackers and dynamic biosensors to measure sweat content, heart rate or any specialized services that the sensor needs to stay in constant contact with the skin.

Boob Tape

The Tape lab works with the large and small boob tape companies to produce adhesive bras and nipple covers. We die cut adhesive bras in size A-DD everyday using our rotary presses. We customize the liner on the adhesive side to make it easy for the consumer to take off the liner and apply the adhesive bras to the skin without damaging the product or the user’s skin. We also manufacture nipple covers using acrylic and silicone adhesives in all kinds of shapes and sizes.

VHB Shapes

VHB is hard to process and die cut. The Tape Lab cuts VHB on both our flat bed presses as well as our Rotary Die cut presses. We offer VHB die cut utilizing butt cutting, sheeting as well as kiss cut parts on a liner.

Protective films

Our protective films work to reduce scratches and markings on products. The Tape Lab die cuts protect film with adhesive on one side to shape for everything from your smart phones to sheets to protect refrigerator door handles.

Foam Gaskets

The Tape Lab custom die cuts foam gaskets with adhesive on one or both sides for every industry. We specialize in laminating the adhesive to the foam and die cutting it to whatever shapes or sizes our customers need for their application. We typically die cut foam with adhesive on our flat bed presses utilizing steel rule dies.