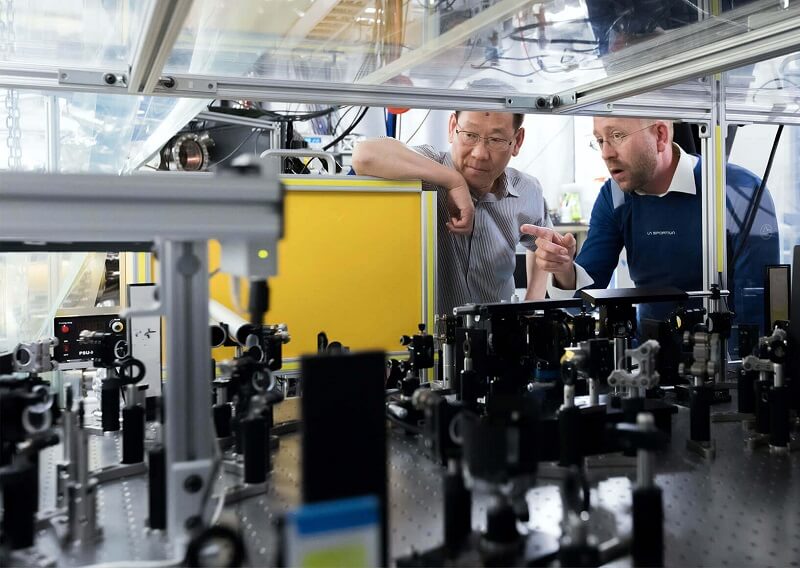

We Transform Adhesive Tape & Flexible Materials

It always starts with a roll. We solve unique problems by taking any flexible material and addressing a specific industry need. Ultimately, a product is born that becomes part of a larger solution—one that we make come to life via our innovative set of engineering services.

Die Cutting

The Tape Lab has the expertise in die-cutting and the capabilities of processing materials, including fabrics, films, foils, foams and other substrates with or without adhesive backings. We will also customize your die cut to your specifications and tight tolerances.

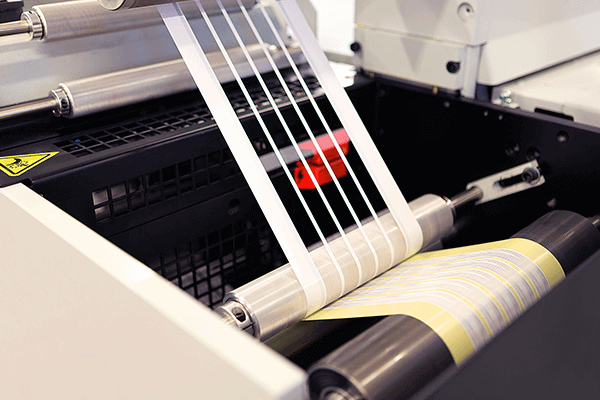

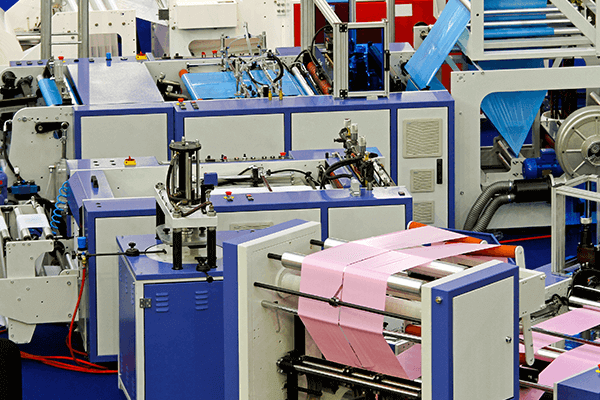

Laminating

Laminating allows The Tape Lab to bring similar or dissimilar materials, in roll or sheet form, together to make a single product construction. We also offer multi-layer laminations that can then be die cut, slit or sheeted for ease of use.

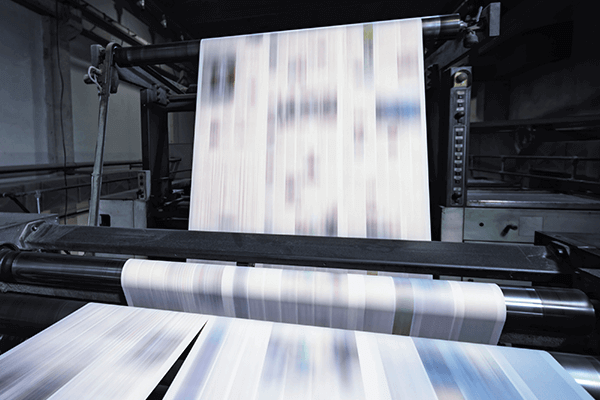

Printing

The Tape Lab provides a wide variety of liners on your custom die cut parts or slit roll goods to get your message on your finished products. Typical printing The Tape Lab performs are: printing your company logos, your product usage and instructions. The Tape Lab utilizes flexographic printing for all custom liners.

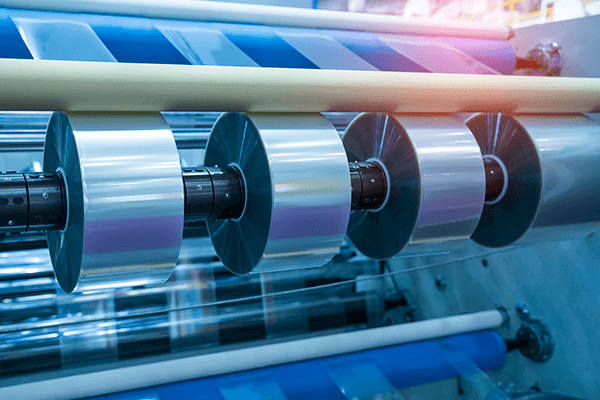

Rewinding

The Tape Lab can rewind jumbo logs (large rolls) of tapes & flexible materials, as well as slit and rewind most roll goods to meet your exact dimensions in any width and length.

Sheeting

The Tape Lab can take your material and sheet it to any size width and length on our old school sheeter or in-line on our rotary presses when tolerance is critical.

Slitting

The Tape Lab uses a variety of slitting methods to slit tapes, films, foams, non-wovens and other flexible materials with or without adhesives. We can slit to custom widths, from large master size logs to micro slit rolls.

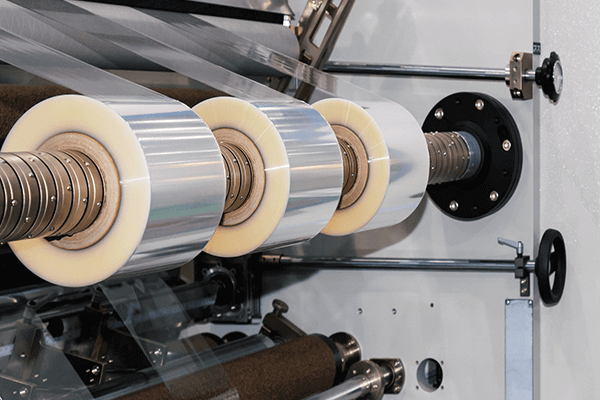

Spooling & Reeling

The Tape Lab has the ability to take tapes and flexible materials and slit and traverse wind them on spools to increase the length of a material for less change over and down time when tapes or foams need to be applied on a moving extrusion line or assembly line.

Packaging & Product Fulfillment

The Tape Lab can do small volume assembly and packaging of your product to meet your specific requirements.

Clean Room Manufacturing & Converting

The Tape Lab operates an ISO 8 (Class 100K) Clean Room. We have the ability to manufacture and package for the medical and health care industries as well as other industries where small particles can adversely affect the manufacturing process or the end product.