Hydrogels are innovative materials that pop up in a variety of places in our daily lives, often working quietly behind the scenes to improve comfort and performance. For example, contact lenses are comfortable because the hydrogel keeps them moist and allows oxygen to pass through to the eye, which is crucial for eye health.

The Tape Lab knows that understanding how hydrogels work and what is hydrogel used for is key for developing new medical products and improving existing ones as part of research and development. Whether it’s creating better medical devices, more effective delivery systems, or even cool new gadgets, knowing how to harness the unique properties of hydrogels can lead to some pretty amazing innovations.

Dive into the world of hydrogels and the uses for the material in the medical field.

What is a hydrogel?

Hydrogels are three-dimensional networks of hydrophilic polymers that can absorb and retain large amounts of water relative to their own mass. These materials are unique because they can swell and maintain their shape when in contact with water or physiological fluids. The structure of a hydrogel consists of a cross-linked polymer matrix that creates a gel-like consistency, providing a medium that is both flexible and moisture-retentive.

Definition and Structure of Hydrogels

At a molecular level, hydrogels are composed of long-chain polymeric molecules that are chemically or physically cross-linked. Cross-linking refers to the process where polymer chains are interconnected, forming a network that stabilizes the structure of the gel. This network allows the hydrogel to swell in water without dissolving, as the polymer chains absorb and hold water within their matrix.

The hydrophilic nature of the polymers used in hydrogels—such as polyvinyl alcohol (PVA), polyacrylamide, or natural polymers like alginate and gelatin—ensures they can interact favorably with water, resulting in high water content within the gel.

Here’s an overview of the key properties of hydrogels:

1. High Water Content

Property: Hydrogels can absorb and retain a substantial amount of water, often up to 90% of their weight.

Significance: This high water content gives hydrogels their gel-like consistency and makes them similar in texture to natural tissues. It also allows them to maintain a moist environment, which is beneficial for applications like wound dressings and contact lenses.

2. Biocompatibility

Property: Many hydrogels are biocompatible, meaning they are well-tolerated by the body’s tissues.

Significance: This property is crucial for medical and biological applications. Biocompatibility ensures that hydrogels do not provoke an immune response or cause irritation when in contact with living tissues, making them suitable for implants, wound dressings, and tissue engineering.

3. Flexibility and Softness

Property: Hydrogels are generally soft and flexible.

Significance: The softness and flexibility of hydrogels make them comfortable to use in applications like contact lenses and soft tissue implants. They can conform to the shape of the body or the eye, providing a snug fit and enhancing user comfort.

4. Absorbency

Property: Hydrogels can absorb and retain fluids, including biological fluids like blood and wound exudates.

Significance: This absorbent property is particularly valuable in wound care, where hydrogels manage exudate and prevent maceration of the surrounding skin. It also helps in drug delivery systems where controlled release is important.

5. Biodegradability

Property: Some hydrogels are biodegradable, meaning they can break down into non-toxic components over time.

Significance: Biodegradability is essential for applications such as tissue engineering and drug delivery systems, where the material needs to eventually degrade and be absorbed or excreted by the body without causing harm.

6. Mechanical Properties

Property: The mechanical strength of hydrogels can vary based on their composition and cross-linking density.

Significance: Mechanical properties like elasticity and toughness are important for different applications. For example, softer hydrogels are used for contact lenses and wound dressings, while more robust hydrogels are used as scaffolds in tissue engineering where structural support is needed.

7. pH and Temperature Sensitivity

Property: Certain hydrogels are responsive to changes in pH or temperature, altering their physical state or properties in response to environmental stimuli.

Significance: This responsiveness is useful for creating smart materials that can release drugs or change behavior in response to physiological changes, enhancing the functionality of drug delivery systems and biosensors.

8. Transparency

Property: Many hydrogels are transparent or translucent.

Significance: Transparency is particularly useful for applications like contact lenses and certain diagnostic devices where visual clarity is important.

9. Swelling Behavior

Property: Hydrogels swell when they absorb water, expanding in size while retaining their shape.

Significance: The swelling behavior allows hydrogels to act as reservoirs for drugs or fluids and can be tailored to control the rate of release or absorption in various applications.

10. Cross-Linking

Property: Hydrogels are typically cross-linked, either physically or chemically, which creates a three-dimensional network structure.

Significance: Cross-linking provides structural stability and integrity to the gel, allowing it to hold its shape and resist dissolution in water. The extent and type of cross-linking affect the mechanical properties and swelling behavior of the hydrogel.

How are different hydrogels classified?

Hydrogels can be classified into several types based on their composition and the nature of their cross-linking:

- Natural Hydrogels: Derived from natural sources like alginate, collagen, or hyaluronic acid. These are often biocompatible and biodegradable, making them suitable for medical applications.

- Synthetic Hydrogels: Made from synthetic polymers such as polyacrylamide or poly(ethylene glycol) (PEG). These can be engineered to have specific properties and are often used in controlled-release systems.

- Composite Hydrogels: Incorporate both natural and synthetic polymers to combine the benefits of both types.

- Responsive Hydrogels: Change their properties in response to environmental stimuli such as temperature, pH, or light.

Benefits of Hydrogels

- High Water Content: Hydrogels can hold up to 90% water by weight. This property is beneficial in mimicking the natural extracellular matrix, which provides a favorable environment for cell growth and tissue regeneration.

- Biocompatibility: Many hydrogels, especially those derived from natural polymers, exhibit excellent biocompatibility. They are less likely to cause an immune response when used in medical applications.

- Flexibility and Softness: The gel-like consistency of hydrogels makes them flexible and soft, mimicking the physical properties of natural tissues. This quality is particularly valuable in applications where comfort and natural feel are important.

- Controlled Release: Hydrogels can be engineered to release drugs or other substances in a controlled manner. This feature is useful in sustained drug delivery systems where a steady release of medication is needed.

- Environmental Responsiveness: Some hydrogels can respond to changes in their environment, such as shifts in temperature or pH. This responsiveness can be harnessed for smart drug delivery or biosensing applications.

- Ease of Processing: Hydrogels can be molded into various shapes and sizes, and their properties can be adjusted through chemical modifications or cross-linking density changes.

Hydrogel Medical Applications

Hydrogels are versatile materials with a range of medical applications due to their unique properties such as high water content, flexibility, and biocompatibility. Here’s a detailed look at their various uses and how they are applied in different medical contexts:

1. Wound Dressings

Use: Hydrogels are used for wound closure and dressings for managing various types of wounds, including burns, ulcers, and surgical incisions.

How Hydrogels Are Used:

- Moisture Management: Hydrogels maintain a moist environment that facilitates healing by promoting cell migration and reducing scab formation. This moist environment helps to accelerate the healing process and minimizes pain.

- Absorption of Exudate: They can absorb excess wound fluid while keeping the wound surface hydrated, preventing maceration (softening of the surrounding skin) and controlling odor.

- Low Adherence: Hydrogel dressings do not stick to skin on the wound bed, making them easy to remove without damaging new tissue or causing discomfort.

2. Contact Lenses

Use: Hydrogel materials are commonly used in the production of soft contact lenses, including advanced silicone hydrogels.

How Hydrogels Are Used:

- Oxygen Permeability: Hydrogels allow greater oxygen flow to the cornea compared to traditional lens materials, reducing the risk of complications like hypoxia (low oxygen levels) and dryness.

- Moisture Retention: The hydrophilic nature of hydrogels helps keep the lens surface hydrated, enhancing comfort and reducing dryness.

- Flexibility: The soft, flexible nature of hydrogel lenses ensures a better fit and increased comfort compared to rigid lenses.

4. Tissue Engineering

Use: Hydrogels are used as scaffolds in tissue engineering to support the growth and development of new tissues or organs.

How Hydrogels Are Used:

- Cell Support: The porous structure of hydrogels provides a supportive matrix for cells to attach, proliferate, and differentiate, which is essential for forming new tissues.

- Customization: Hydrogels can be engineered with specific mechanical and biochemical properties to closely mimic the natural extracellular matrix, which is critical for tissue regeneration.

- Biocompatibility: They are designed to be compatible with living tissues, minimizing immune responses and facilitating integration with the body.

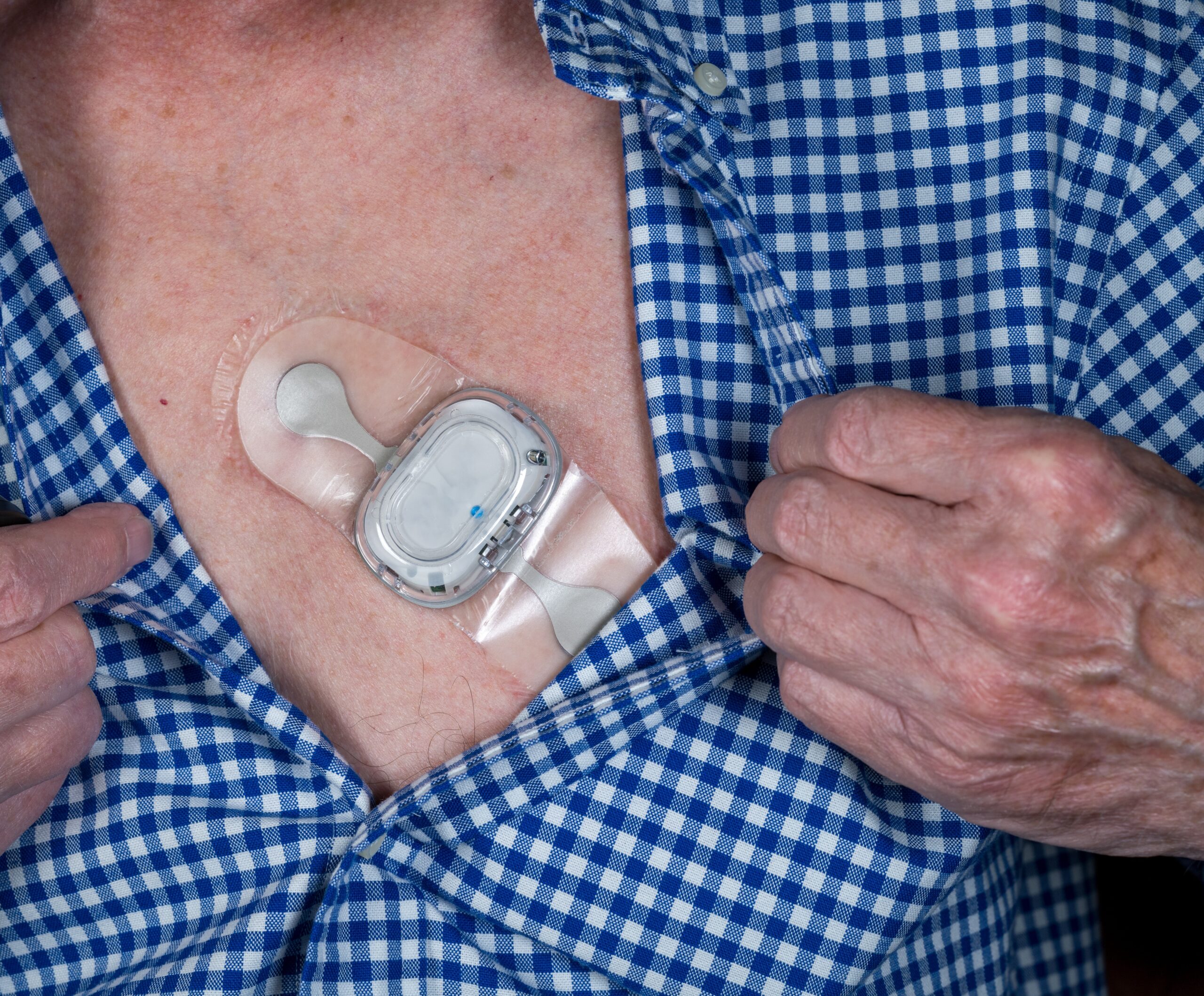

5. Surgical Implants

Use: Some medical implants and prosthetics incorporate hydrogel materials, including soft tissue implants and certain orthopedic devices.

How Hydrogels Are Used:

- Flexibility and Comfort: Hydrogels offer a soft, flexible material that can mimic the feel and function of natural tissues, providing comfort and reducing stress on surrounding tissues.

- Reduced Immune Response: Their biocompatibility helps prevent adverse reactions or rejections when implanted in the body, making them suitable for long-term use.

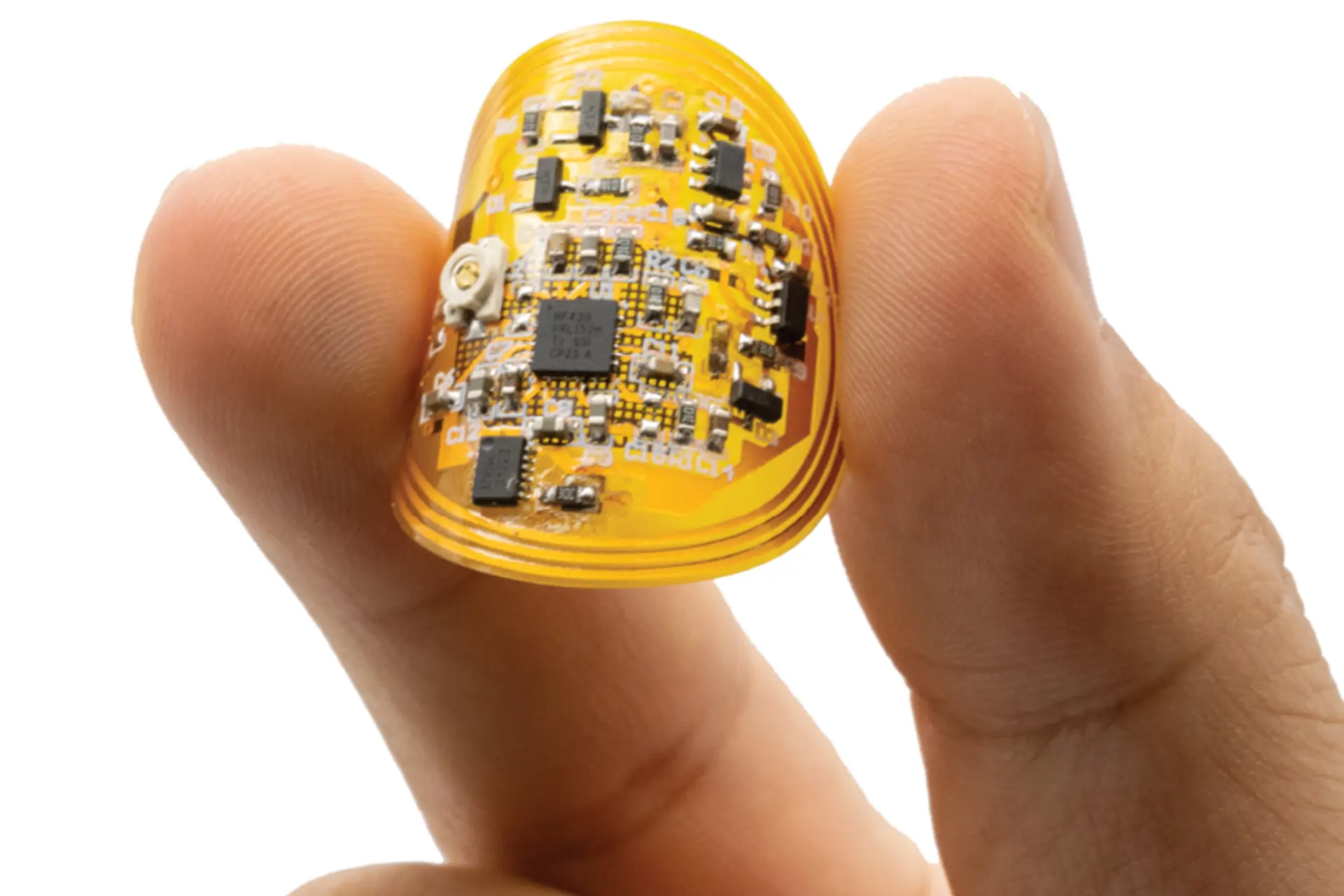

6. Diagnostic Devices

Use: Hydrogels are used in diagnostic devices and biosensors for detecting and measuring various biological substances.

How Hydrogels Are Used:

- Responsive Properties: Hydrogels can be engineered to change their properties, such as color or volume, in response to specific biological signals or analytes, making them useful for sensitive and specific assays.

- Integration with Biological Molecules: They can incorporate reagents or biomolecules that interact with target substances, enhancing the accuracy and efficiency of diagnostic tests.

7. Cryopreservation

Use: Hydrogels are employed in cryopreservation to protect biological samples like cells and tissues during freezing and thawing.

How Hydrogels Are Used:

- Ice Crystal Prevention: Hydrogels help to prevent the formation of ice crystals, which can damage cells during the freezing process by retaining water and maintaining a stable environment.

- Preservation of Viability: By minimizing ice formation and preserving cell integrity, hydrogels improve the success rate of cryopreservation and the recovery of cells and tissues post-thawing.

Hydrogels represent a versatile and valuable class of materials with numerous benefits and applications, particularly in the medical field. Their high water content, biocompatibility, flexibility, and the ability to respond to environmental stimuli make them ideal for a range of uses from wound care to advanced tissue engineering. As research continues to expand, the applications and capabilities of hydrogels are likely to grow, further enhancing their role in medicine and beyond.

Get a Custom Medical Adhesive Created for Your New Product

At The Tape Lab, we’re not just manufacturing adhesives and other flexible medical materials; we’re crafting partnerships to bring your custom innovations to life. We design, manufacture, and transform adhesives for your personalized medical solution.

Already have an idea of what you need? Want to pick the brain of an expert? Contact The Tape Lab or request a quick quote, and let’s combine your vision with our knowledge and industry-leading capabilities to create a custom adhesive solution.